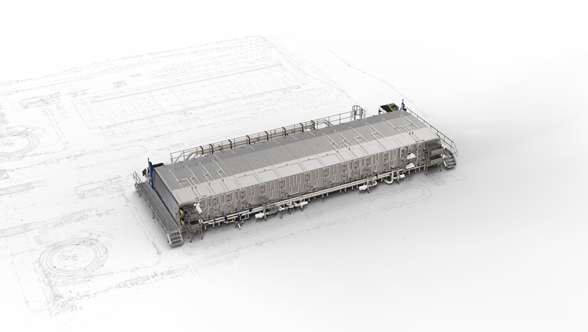

Lavasonic HI: rethinking bottle washing for a more efficient future

Bottle washing is one of the most resource-intensive processes in beverage production – especially when it comes to returnable containers. In this video, Marcus Wagner from Krones’ Cleaning Technology department presents Lavasonic HI, a newly developed double-end bottle washer that redefines efficiency, flexibility, and sustainability.

The Lavasonic HI system introduces a demand-oriented cleaning approach with five selectable programs tailored to different bottle conditions. Whether dealing with lightly soiled bottles or heavily contaminated ones, the system adapts in real time – reducing unnecessary energy and water usage.

Key innovations include:

• Ultrasonic pre-treatment for loosening dirt and labels

• Unique bottle locking mechanism that allows higher jetting pressure while reducing mechanical stress

• Up to 40 percent shorter treatment time

• Lower cleaning temperature (from 80 °C to 70 °C)

• Savings of up to 35 percent CO₂ emissions, 30 percent thermal energy, and 20 percent fresh water

The result: Bottles stay in circulation longer, cleaning becomes more precise, and operational costs drop significantly.

Sounds interesting? Our expert shares more insights in the video – take a look!

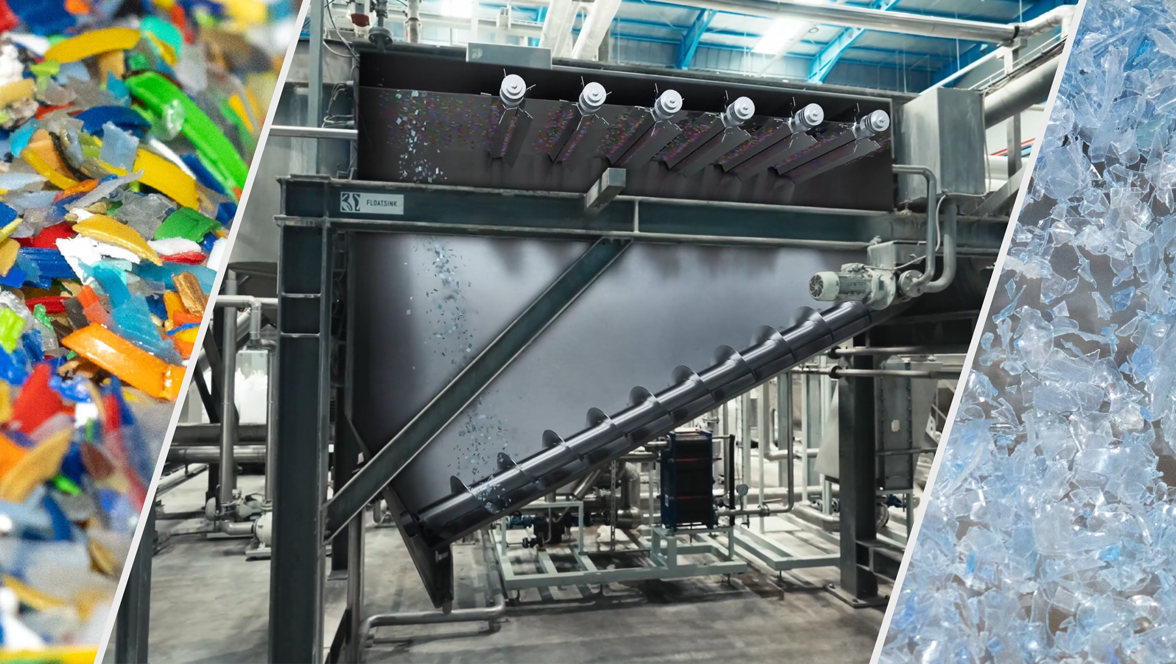

Exploring the world of alternative proteins and bioprocessing

What do beer, cultured meat, and insulin have in common? They are all products that originate from one of the fields of biotechnology. This means: Living cells or their components, such as enzymes, are used to convert a substrate into specific products.

For beer, this is the fermentation process – and this is where Steinecker comes into play. With 150 years of experience, the Krones subsidiary knows beer and the brewing process probably better than any other company in the world. Since a few years, this experience has been adapted to alternative proteins. Here, cells are propagated in a bioreactor which was developed on the basis of the fermentation unit Poseidon, known from the brewing technology.

But it cannot be used for food or beverages only! During his lecture at drinktec, Alexander Scheidel from Steinecker explained how the know-how from producing beer and alternative proteins can also be adapted to other bioprocesses, e.g. in the agricultural, marine, or pharmaceutical industries.

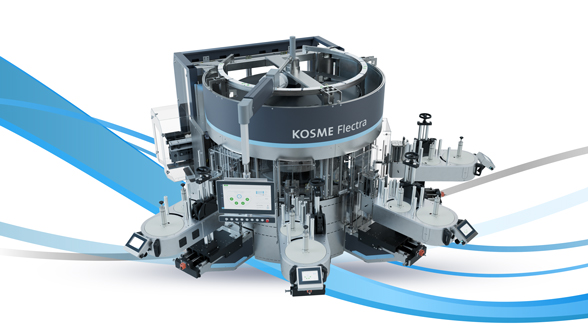

Compact, smart, and ready for the future – discover the new Contipure AseptBloc

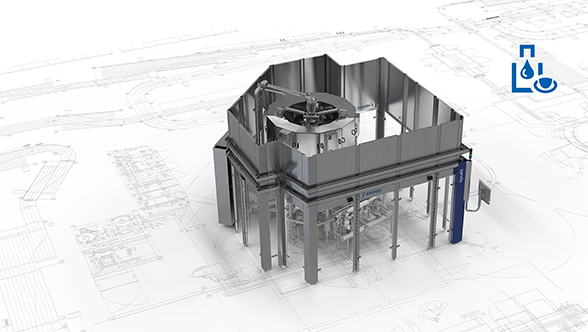

In a fast-evolving industry where flexibility, sustainability, and product safety are key, Krones presents a true game-changer: the new compact version of the Contipure AseptBloc.

In the dynamic world of sensitive beverage production, manufacturers face increasing demands for flexibility, sustainability, and uncompromising product safety. Krones has responded with a breakthrough solution: the new compact version of the Contipure AseptBloc – engineered specifically for lower output ranges without sacrificing performance.

The aseptic block offers a fully isolated design that ensures maximum hygiene and product integrity. With a footprint of just 100 square meters, it’s ideal for brownfield installations or facilities with limited space. The system supports outputs starting from 8,000 bottles per hour, making it a perfect fit for small to mid-sized operations or new product launches.

Key technical highlights include:

• Automated head adjustment on the capper and adaptive filling valves for seamless changeovers between product types and bottle formats

• Over 50 percent footprint reduction compared to standard aseptic blocks, contributing directly to lower building and operational costs

• Integrated sustainability features, such as lightweighting options and optimised packaging flexibility, enabling reduced carbon emissions and enhanced shelf appeal

• Modular design that supports a wide range of packaging formats – from wraparound cartons to hybrid solutions – with minimal downtime

Curious to see how visions become reality? In the video, Krones expert Nick Kolter takes you on a journey through the challenges of aseptic filling and how this new solution ticks all the boxes – from safety and flexibility to sustainability and packaging design.

Krones.world – your central gateway to all digital services

Krones.world brings together all our digital services on one unified platform. No more jumping between systems or searching for the right tool – everything you need is just a few clicks away. Whether it’s ordering spare parts, monitoring production, or accessing customer support, Krones.world is divided into three distinct areas that together make your digital experience simple, efficient, and seamless.

This sounds too good to be true? Get convinced by our experts who were speaking at the Krones Forum during drinktec by watching the video replay. They don’t just give you some information about Krones.world in general, but also cover topics like e-shop, production and customer service.

If you don’t have the opportunity to watch the video, we’ve summarized the three areas of Krones.world for you:

Krones.shop – Spare parts ordering made simple

Need a spare part for your Krones machines or systems? With Krones.shop, the entire process – from inquiry and quotation to order and delivery – is transparent and straightforward. You can easily keep track of your orders and monitor their status online at any time. The personalised eCat helps you quickly find the right part, reducing errors and saving valuable time. Digital documents, including invoices, are always accessible, and for maximum efficiency, you can seamlessly integrate the ordering process into your own system. When speed matters most, Rapid Part On Demand enables you to print qualified spare parts directly on-site – making the future of spare parts supply a reality today.

Krones.world Production – The digital connection to your machine

With Krones.world Production, our goal is to provide you with transparent, real-time monitoring of your entire production environment – whether via browser or directly at the machine’s HMI. Thanks to intelligent data connectivity, we help ensure your equipment stays up to date in terms of software and security. You can rely on smooth and secure operations, while additional digital services and remote consulting can be flexibly added to further boost the efficiency and availability of your line. And because we’re continuously developing Krones.world Production, you can look forward to even more digital services and features in the future.

Krones.world Customer Service – Always by your side

With Krones.world Customer Service, you have a clear overview of your individual support cases, service contracts, and all relevant documents at any time. Transparent dashboards keep you up to date on the status of your requests, while direct communication with the Krones support team – whether by phone, email, remote service, or directly through the portal – ensures that issues are resolved quickly and efficiently. As we move from reactive to proactive support, you benefit from expert assistance that monitors your systems, keeps your production reliable, and allows you to fully focus on your core business.

Pioneer of sustainability: technological milestones in brewing

In the past 25 years, Steinecker paved the way to an energy self-sufficient brewery: from the introduction of the EquiTherm system in 2010 to the holistic Brewnomic concept which has been presented for the first time in 2016. One important puzzle piece is Phoenix BMC, a biomass conversion system which brings the upcycling of residual materials from the brewing process and energetic conversion to a whole new level.

If you want to learn more about it, we invite you to listen to Peter Gattermeyer, Head of Steinecker Technology and Engineering. In his presentation which has been held during drinktec 2025 he walks you through the idea of how breweries can get closer to energy independence and CO~2~ neutrality.