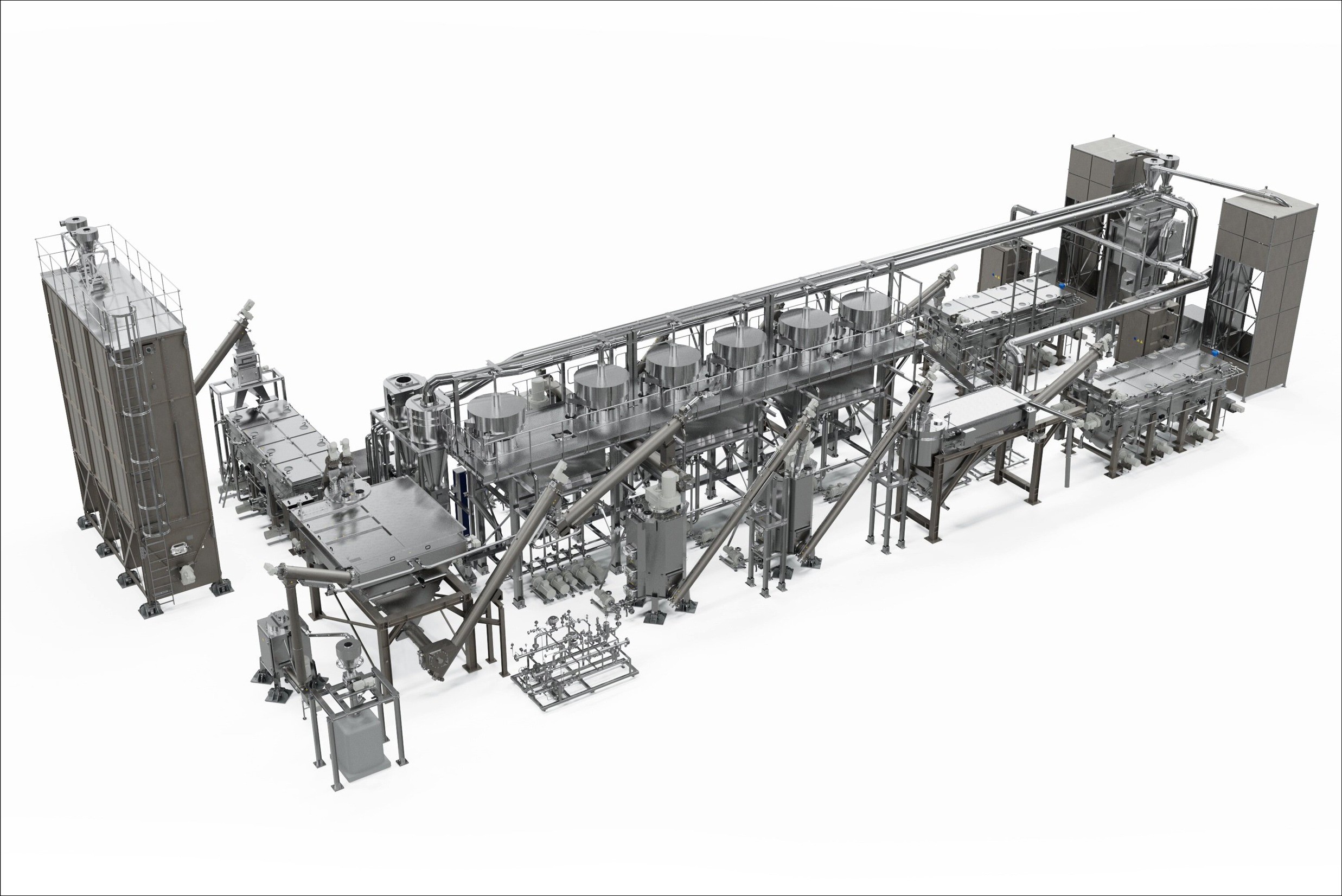

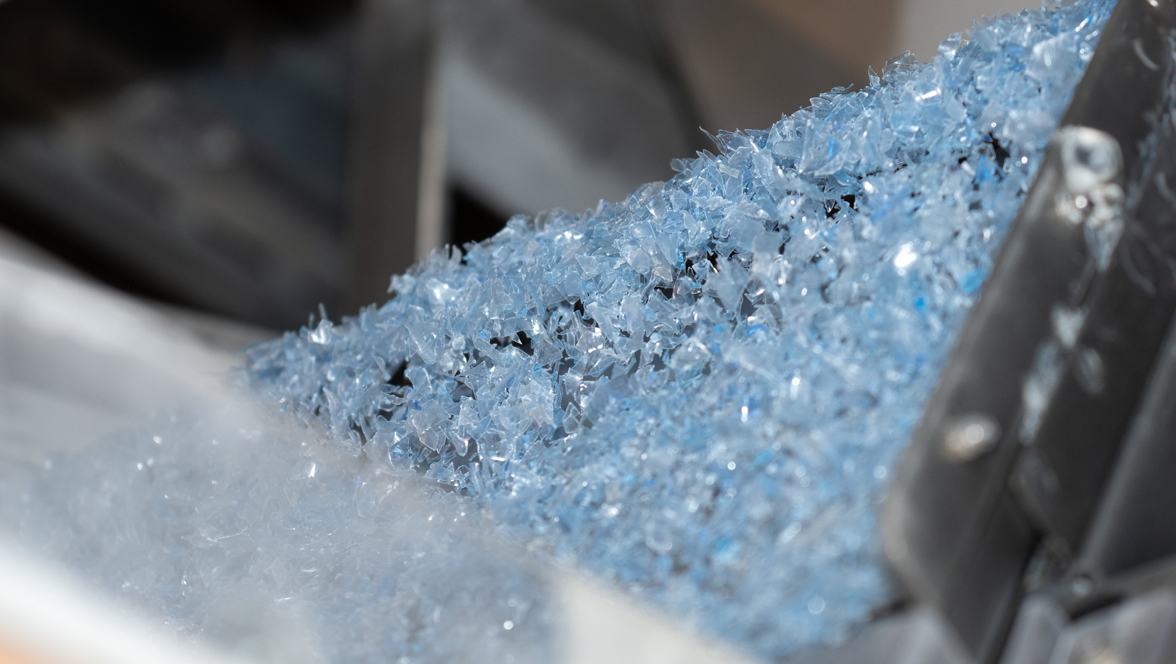

From compressed bales of plastic waste to food-grade flakes or pellets: a plant from Krones Recycling covers the entire plastics recycling process. The plastic waste is sorted, broken down into flakes, washed and then decontaminated.

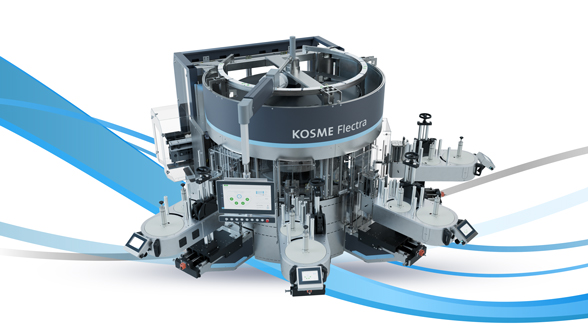

The demands on a washing module are high. After all, its job is to ensure that the finished product reliably meets a certain quality standard, which includes both cleanliness and minimized production of fine particles during recycling. “Flakes smaller than two millimeters are removed because they don’t process as well. So, our machines are designed to provide gentle handling, to prevent them occurring,” says Mathias Dawartz, Head of Project Execution and Process Engineering at Krones Recycling GmbH. “At the same time, we emphasize efficient, sustainable use of energy and water in our machines and lines.”

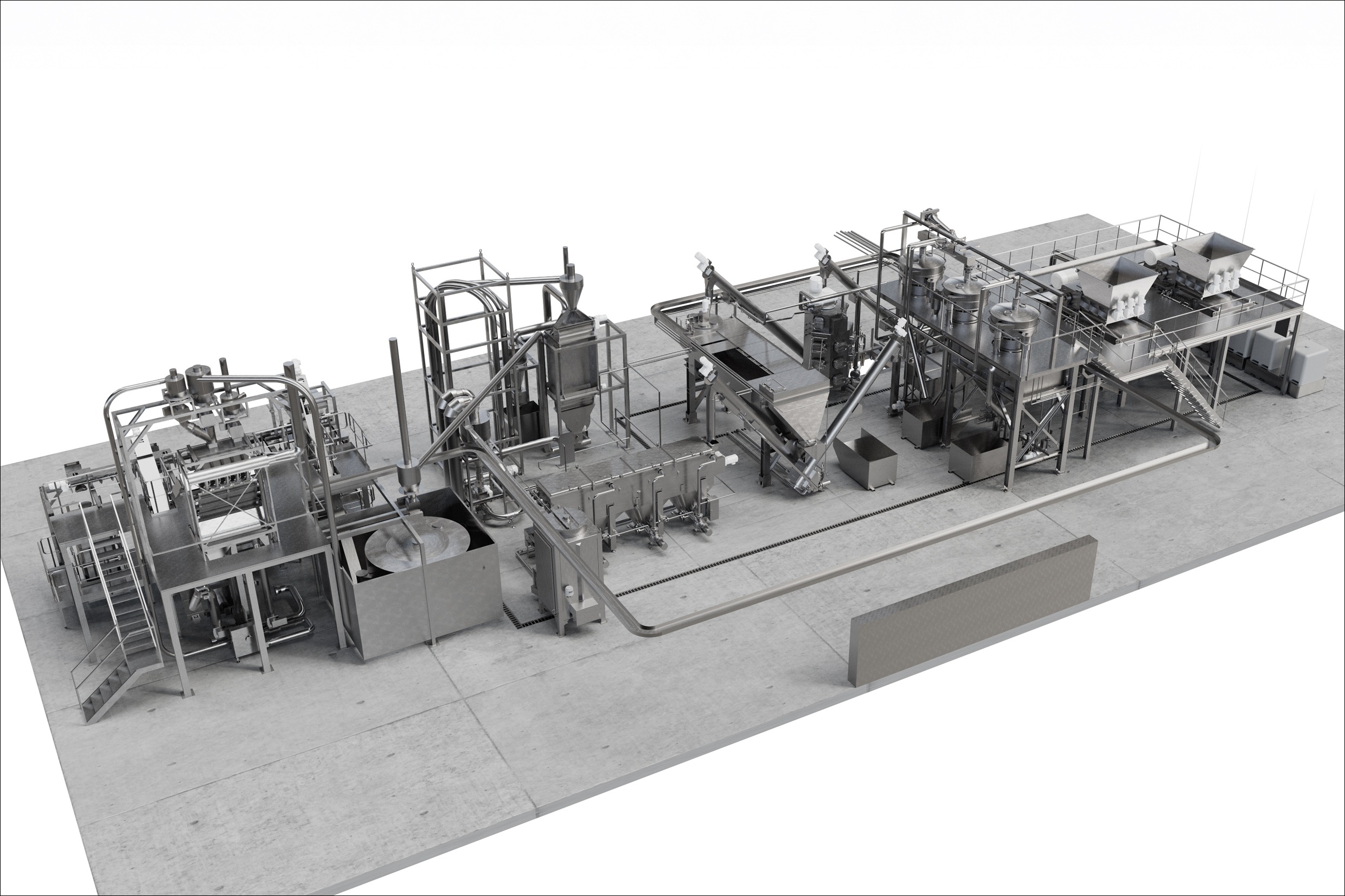

The new, more compact configuration of the washing module, MetaPure Compact, offers customers a resource-saving recycling process that generates fewer fine particles – and it is made of the usual high-quality stainless steel. The system is also quite versatile when it comes to different types of plastic: The MetaPure Compact is suitable for processing PET and HDPE and, thanks to the consistently high washing quality, is also perfect for bottle-to-bottle recycling. Its gentle process makes the MetaPure Compact ideal for brittle materials like PET food trays, PP and PS because it minimizes the production of fine particles. And on a reduced footprint at that, as Managing Director Michael Gotsche explains: “With a considerably smaller footprint and an input capacity ranging from one and a half to six tons per hour, the new compact configuration is ideal for sites with limited space or for retrofitting in existing buildings.”