Washing, Grinding, Decontamination: Modules for plastics recycling

Krones Recycling offers solutions for the entire plastics recycling process. The individual modules for pre-sorting and post-sorting, grinding, cleaning, and decontamination can be integrated into existing plants or combined to form a turnkey recycling factory. At every processing stage, we attach great importance to treating the material with special care so as to ensure maximum output and the best quality of recycled plastic. In doing so, we always focus on the efficient and sustainable use of energy and resources.

At a glance:

- Production of high-quality recyclates from all types of plastics, including PET trays and films.

- Exceptional washing quality thanks to decades of experience

- Highly efficient processes for water and energy-saving systems

- Very low fine particle production thanks to the use of slowly rotating units

- For the highest end-product quality: all product-contacting parts in high-quality stainless steel design

- Available in the form of individual machines or as a complete line

- Individual support from planning through to acceptance

- Support from the Lifecycle Service team throughout the entire lifecycle of your machinery

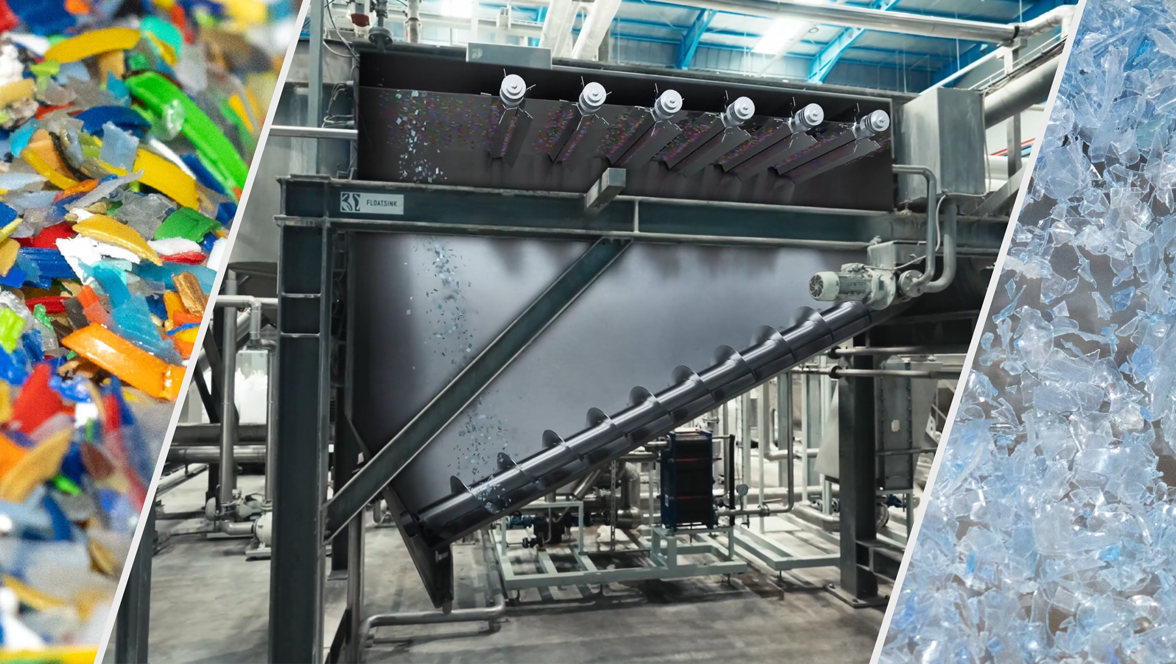

As popular packaging for a wide range of products, plastic waste still often contains residues of cleaning agents, personal care products, and beverages – and also other aggressive substances such as petrol, which must be reliably removed during washing along with dirt and adhesives.

The washing process at Krones Recycling is therefore designed to thoroughly clean even heavily soiled materials. Depending on the degree of contamination, it includes a pre-treatment system, sink-float tank, hot caustic washing in a patented intensive washer, and multi-stage post-washer. The material is then carefully dried. This results in hygienically clean plastic flakes that are ideal for further processing into new, high-quality packaging – even for food contact.

As popular packaging for a wide range of products, plastic waste still often contains residues of cleaning agents, personal care products, and beverages – and also other aggressive substances such as petrol, which must be reliably removed during washing along with dirt and adhesives.

The washing process at Krones Recycling is therefore designed to thoroughly clean even heavily soiled materials. Depending on the degree of contamination, it includes a pre-treatment system, sink-float tank, hot caustic washing in a patented intensive washer, and multi-stage post-washer. The material is then carefully dried. This results in hygienically clean plastic flakes that are ideal for further processing into new, high-quality packaging – even for food contact.

Perfect decontamination of PET is the number one prerequisite for achieving food-grade flakes or pellets. Due to the fact that flakes can be decontaminated quicker than pellets, the decontamination technology from Krones Recycling stands out thanks to its lower energy requirement and gentle material handling. The material is first dried and heated, then decontaminated to remove any migrated substances it may contain. Where required, solid-state post-condensation (SSP) can be used to increase the intrinsic viscosity which may have decreased during previous recycling stages. Following the SSP, there are three optional end-product alternatives to choose from: either the food-grade flakes are directly processed inline to form preforms or film – or pellets are produced. For extra safety, the melt is deaerated in an additional cleaning step during pellet extrusion.

Perfect decontamination of PET is the number one prerequisite for achieving food-grade flakes or pellets. Due to the fact that flakes can be decontaminated quicker than pellets, the decontamination technology from Krones Recycling stands out thanks to its lower energy requirement and gentle material handling. The material is first dried and heated, then decontaminated to remove any migrated substances it may contain. Where required, solid-state post-condensation (SSP) can be used to increase the intrinsic viscosity which may have decreased during previous recycling stages. Following the SSP, there are three optional end-product alternatives to choose from: either the food-grade flakes are directly processed inline to form preforms or film – or pellets are produced. For extra safety, the melt is deaerated in an additional cleaning step during pellet extrusion.

The better the pre-sorting and preparation of the initial material, the better the quality and purity of the recycled plastics will be at the end. At the front end, after breaking up the plastic bales, Krones Recycling therefore primarily focuses on removing contaminants such as iron or other metals and, where necessary, removing any labels before separating the different types of plastic in the raw material into separate fractions of one colour or type. This is achieved with the help of sensor or magnetic technologies, among other things. The material is then optimally prepared for the subsequent processes.

The better the pre-sorting and preparation of the initial material, the better the quality and purity of the recycled plastics will be at the end. At the front end, after breaking up the plastic bales, Krones Recycling therefore primarily focuses on removing contaminants such as iron or other metals and, where necessary, removing any labels before separating the different types of plastic in the raw material into separate fractions of one colour or type. This is achieved with the help of sensor or magnetic technologies, among other things. The material is then optimally prepared for the subsequent processes.

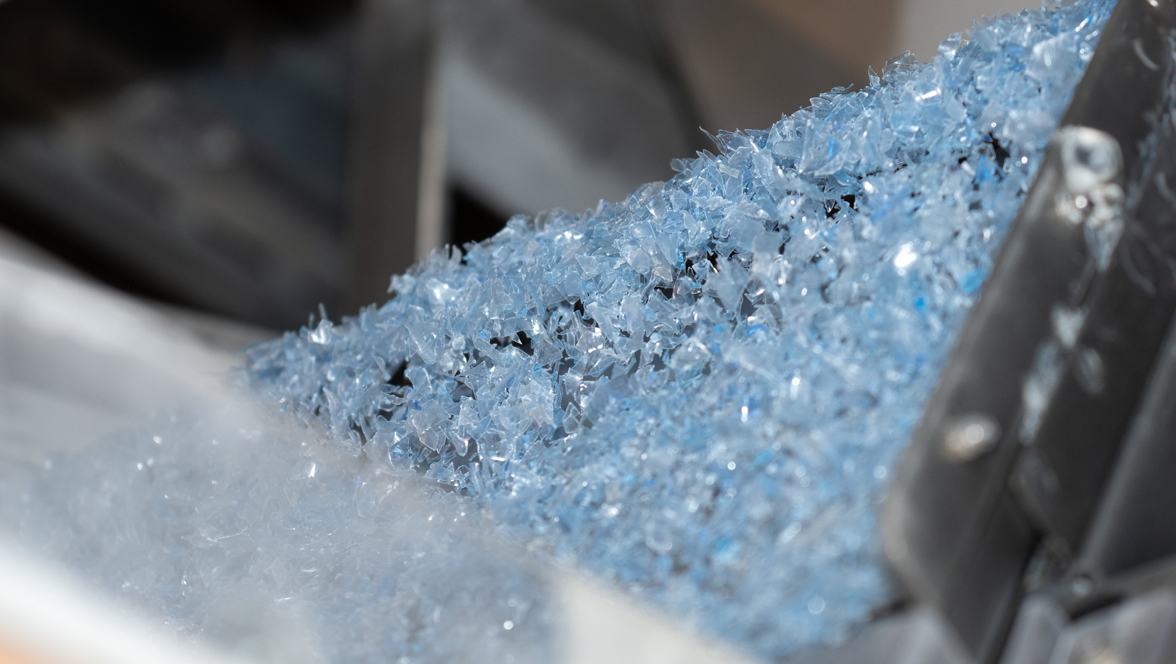

The grinding of plastic waste into flakes requires the use of powerful machines that operate gently even with brittle plastics. Krones Recycling relies on energy-efficient technology with energy-saving operation and sustainable use of water. The wet mills use process water from a self-developed water cascade – without consuming any fresh water. In addition, great importance is placed on the use of maintenance-friendly designs and ergonomic solutions that reduce the workload for staff on a daily basis and increase operational safety.

The grinding of plastic waste into flakes requires the use of powerful machines that operate gently even with brittle plastics. Krones Recycling relies on energy-efficient technology with energy-saving operation and sustainable use of water. The wet mills use process water from a self-developed water cascade – without consuming any fresh water. In addition, great importance is placed on the use of maintenance-friendly designs and ergonomic solutions that reduce the workload for staff on a daily basis and increase operational safety.

After the washing process, the plastic flakes are checked once again for purity of colour and type during post-sorting. Camera-based systems sort them precisely according to their size, colour and plastic type. Here, Krones Recycling combines its partners’ solutions with its own products to create a holistic, innovative post-sorting concept. The hoppers, big bag filling stations, and conveyor systems, among other things, are developed and produced in-house. This precise post-sorting procedure significantly extends the range of applications suitable for the recycled flakes – even allowing them to be further processed for use in food-contact material.

After the washing process, the plastic flakes are checked once again for purity of colour and type during post-sorting. Camera-based systems sort them precisely according to their size, colour and plastic type. Here, Krones Recycling combines its partners’ solutions with its own products to create a holistic, innovative post-sorting concept. The hoppers, big bag filling stations, and conveyor systems, among other things, are developed and produced in-house. This precise post-sorting procedure significantly extends the range of applications suitable for the recycled flakes – even allowing them to be further processed for use in food-contact material.