This time, in addition to the bottling and packaging machinery, Winzer Krems has also ordered the cleaning and wine filtration systems from Krones – and is thus truly getting it all from a single source.

The last combined glass line for returnable and non-returnable containers that Krones installed at Winzer Krems ran for 20 years – and it served the Austrian wine cooperative well. Now, Winzer Krems has had a new line installed for non-returnable glass bottles – and has once again chosen Krones for the job.

Warning: Undefined array key "page" in /data/www/kronescom/htdocs/en/company/press/magazine/reference/everything-from-a-single-source-a-krones-glass-line-for-winzer-krems.php on line 1250

Warning: Array to string conversion in /data/www/kronescom/htdocs/en/php/Helper.class.php on line 605

Warning: Array to string conversion in /data/www/kronescom/htdocs/en/php/Helper.class.php on line 605

Strong on exports

Wine-lovers across Austria (and far beyond) recognize Sandgrube 13 in Krems an der Donau as the epitome of premium wine culture. Its Grüner Veltliner in particular – a variety that has its origins in Lower Austria – is associated with the highest quality and the assurance of an exquisite wine experience. Winzer Krems is a wine producers’ cooperative in a region whose wine-growing tradition can be traced back nearly two thousand years. The area cultivated by its vintners stretches over roughly 1,200 hectares some 80 kilometers west of Vienna in the Danube valley, at the entrance to one of Europe's most beautiful river valleys: the Wachau.

Grüner Veltliner grapes account for around 60 percent of the cooperative’s annual production volume of approximately seven million liters. Other white varieties – Riesling first and foremost – make up another one-tenth or so. The remaining 30 percent of grapes cultivated are black-skinned varieties for making red wines, primarily the Blauer Zweigelt. “Demand for red wine has been increasing steadily. And that’s great news for us. Due in part to climate change, our region is becoming increasingly hospitable to growing black grapes,” explains Managing Director Ludwig Holzer. “The fruity style of our wines is very popular on the market.”

The Lower Austria-based wine cooperative does the lion’s share of its business abroad. Exports have surged in recent years and now make up 60 percent of sales. Winzer Krems ships its wines to 25 countries, with Germany topping the list. In Austria, half of domestic sales go to the food-service industry, which was hit hard by coronavirus restrictions in the last two years. Winzer Krems was able to offset those losses with higher exports, gaining new buyers as far away as Australia, Japan, and South Korea. And now that those numbers have flattened out due to inflation, a reviving restaurant trade is, in turn, taking up that slack.

The key to success lies in the details of the process

Winzer Krems began updating its entire plant back in 2019 and has since installed a 6.5-million-liter fermentation and maturation cellar, wine filling equipment, and a bottle storage system. "A €37 million investment is no small matter for a company whose annual revenue totals around €30 million," says Managing Director Ludwig Holzer. Especially considering that they first had to get the 800 or so member vintners (all of them co-owners) on board, as they also have a say in such decisions. "That takes a lot of mutual trust," stresses Holzer. "In all of our decision-making, we have to keep the big picture in mind: Winegrowers and members on the one hand, sales and distribution on the other, and connecting the two is the technology in the cellar and in the bottling hall. And on that point, we simply had to invest in the future."

But the challenges of a wine cooperative sometimes extend beyond decision-making. Consumers tend to view large-scale operations like Winzer Krems with a certain degree of skepticism. "So we have to do all the more to ensure the quality of our wines, to stand out favorably on the market. For that reason, Winzer Krems relies on extremely well-organized planning for the optimal harvest times in each individual vineyard, then completely separates the different varieties and terroirs, practices whole-cluster pressing – without de-stemming and without cold maceration, so that the freshly harvested grapes can be brought to the press as quickly as possible. And finally, the cooperative matures its wines in a reductive, low-oxygen environment with as little fining and sulfites as possible. "The results of this controlled, natural production are fruity, clean wines. Because we want our wines to go down well – and the second glass should be just as agreeable as the first. Precisely this philosophy is what consumers appreciate," explains Holzer.

Part of the package: a new filling system

Winzer Krems also had a new bottling hall built specifically for this line. That allowed the old line to continue to operate until the new line was up and running – so production never stopped.

The new line went into operation in February 2022 and can fill up to 15,000 0.75-liter non-returnable glass bottles per hour – which is around 20 percent more than the previous line. But the capacity upgrade wasn't the main focus of this project. Further increasing quality was. Winzer Krems also place a great deal of emphasis on sustainability. As such, the new filling line – like the cellar – is powered by electricity generated on a 125-kilowatt peak (kWp) photovoltaic system and the power supply was switched from gas to district heating.

Ludwig Holzer finds that the new line is very quiet. And it achieved an efficiency of over 98 percent during acceptance testing. Winzer Krems opted to outsource the filling of the small share of wine that goes into returnable bottles. Now, the company is able to produce ten million non-returnable glass bottles in single-shift operation each year. "That means we also have some capacity for contract bottling," says Ludwig Holzer with a wink.

The new line in detail

It fills eleven different bottle formats ranging in volume from 0.25 to 1.0 liters and includes the following:

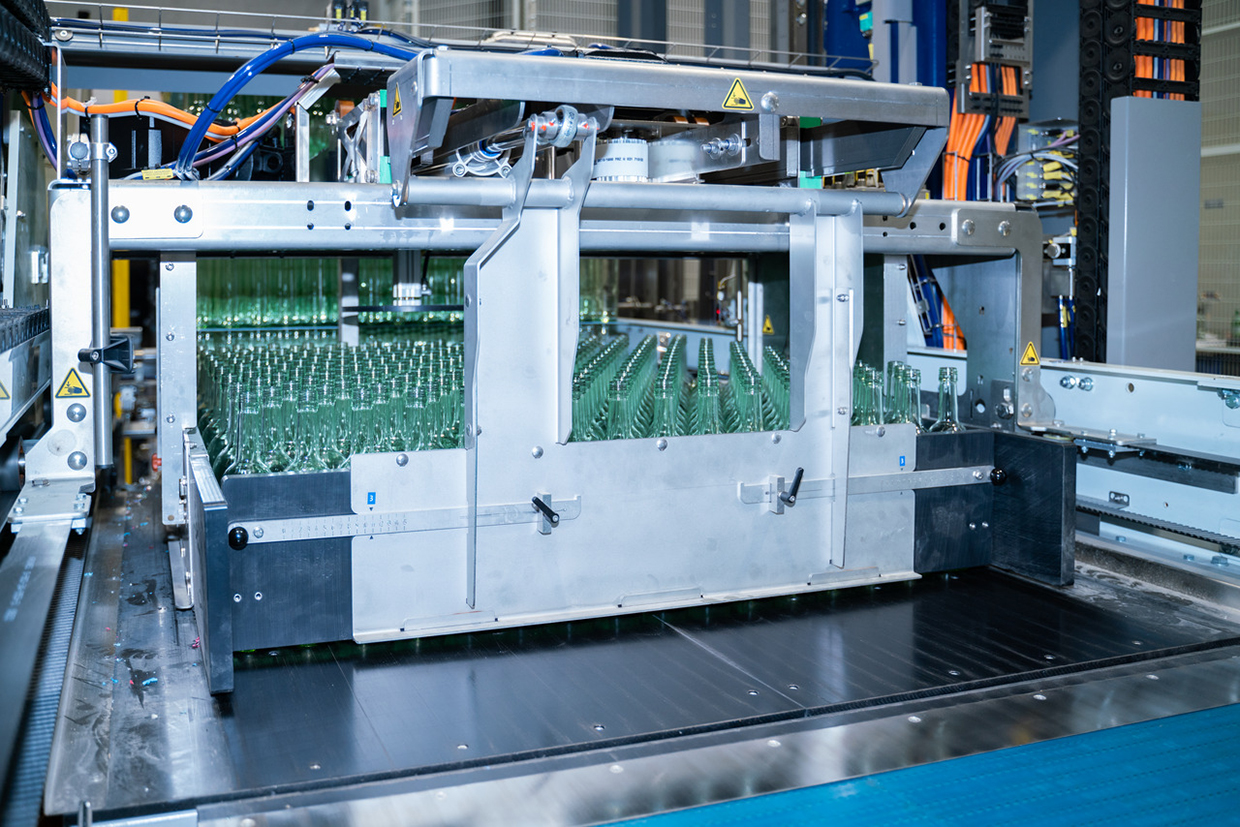

- Pressant Universal 1N sweep-off depalletizer

- Linatronic M empty-bottle inspector

- Stainless-steel-covered conveyor to the filler

- Rinser-filler-capper/corker block with a Moduljet rinser, Modulfill HRS filler, and two options for closing the bottles: aluminum screw caps and natural corks plus a capsule applicator*

- Checkmat FM-X inspector for checking fill level by way of x-ray

- Glideliner

- Linadry container dryer

- Autocol labeler with four stations for pressure-sensitive labels

- Checkmat E inspector for checking label placement

- Variopac Pro W packer

- Modulpal Pro 2AC palletiser

* Thanks to the two bottle-closing units, Winzer Krems is able to use PVC long-skirted screw caps, short-skirted MCA screw caps, or natural cork closures for upmarket vinotheque wines.