Safe blow moulding process, immaculate bottle quality

Preform and container inspection - directly in the blow moulder

You want to make sure that only faultless preforms enter the blow moulding process? You also want to make sure that only faultlessly blow-moulded bottles are fed to the filler afterwards? PET-View grants both. The inspection system checks both, preforms and bottles using various quality criteria and systematically rejects faulty material.

Whether these are being processed on a stretch blow-moulder for the first time or repeatedly is irrelevant: Because PET-View applies the same thoroughness to virgin material as well as to preforms and containers made from up to 100 percent recyclate.

At a glance

- Inspection of preforms

- Inspection and quality testing of bottles that have just been blow-moulded

- Equally suitable for virgin and rPET

- Wide range of inspection criteria

- Integration into the blow moulder

- Operation via the blow moulder's touch-screen panel

Overview: Which functions are possible?

| For preforms | Inspection criteria |

|---|---|

|

360° Side wall |

|

|

Sealing surface |

|

|

End-Cap |

|

| Gate |

|

| For containers | Inspection criteria |

|---|---|

|

Sealing surface |

|

|

Base |

|

|

Contour and side wall |

|

| Wall thickness |

|

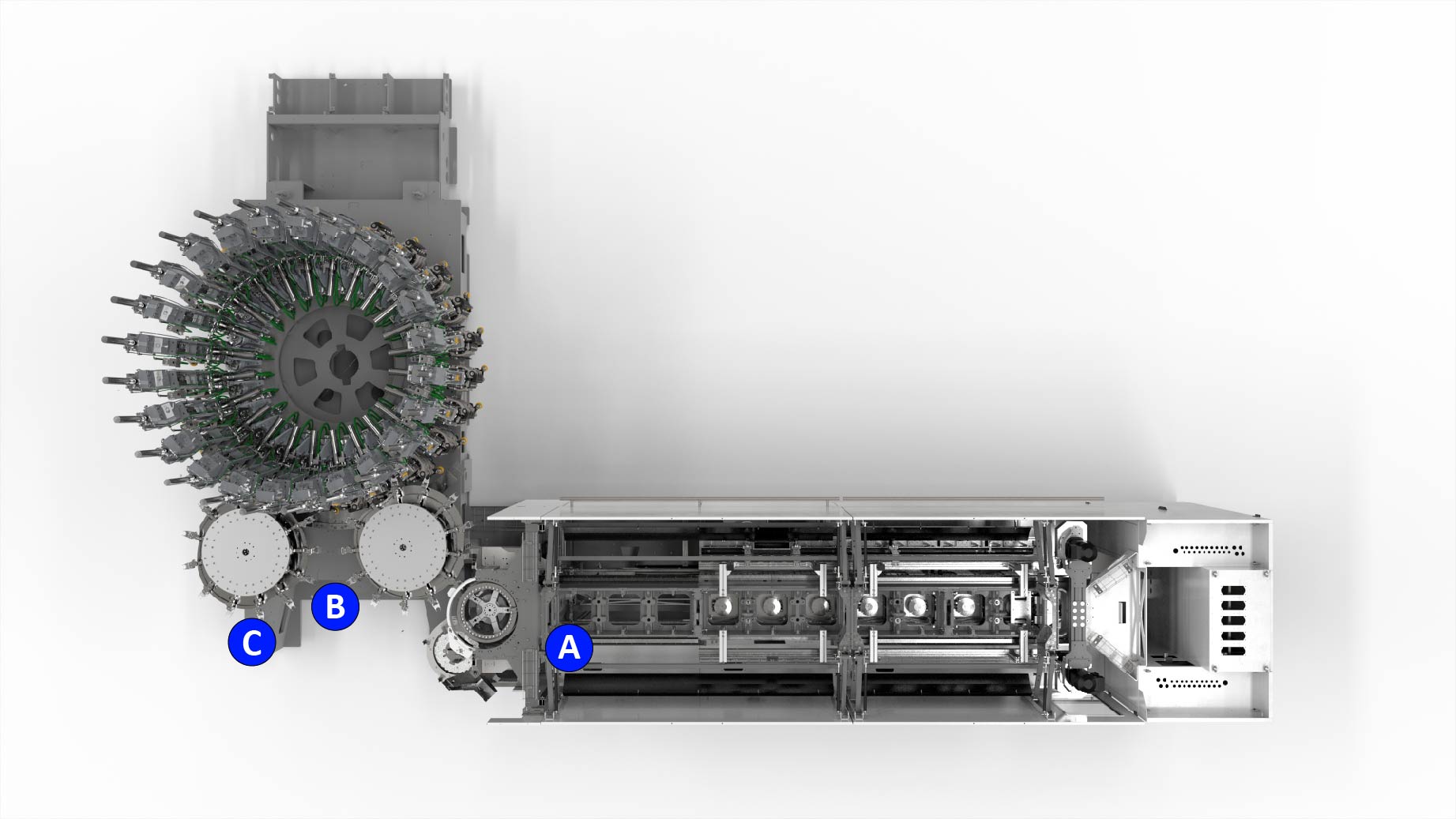

Overview: What happens where?

Preform inspection: Gate

Rejection at position "A"

Preform inspection: Side wall

Reading the mould number (optional)

Rejection at position "B"

Preform inspection: Sealing surface

Rejection at position "B"

Preform inspection: End-cap

Rejection at position "C" (after pre-blowing)

Container inspection: Side wall quality inspection/wall thickness measurement

No rejection

Container inspection: Sealing surface, base, contour and side wall

Rejection at position "C"

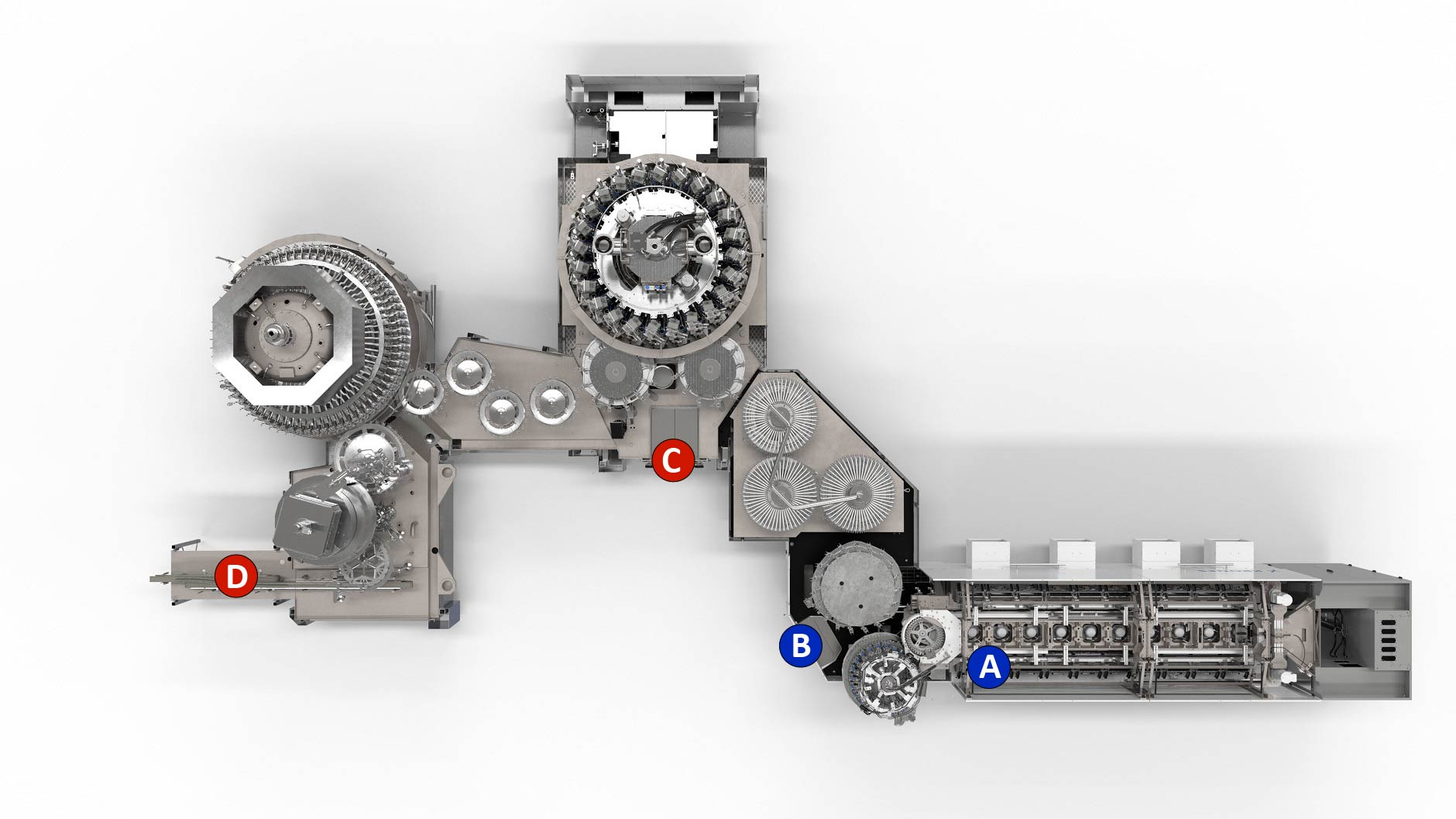

PET-View in the Contipure AseptBloc with rotary rinser

Preform inspection: Side wall

- Contamination

- Banana shape

- Trapped air

- Length of the gate

- Length and diameter

- Reading the mould number (optional)

Rejection at position "B"

Preform inspection: Gate

- Gate position

- Banana shape

Rejection at position "A"

Preform inspection: Sealing surfaces

- Ovality

- Damage

- Opaque contamination

Rejection at position "B"

Preform inspection: End-cap

- Contamination

- Gate not in the centre

- Banana shape

- Colour (optional)

Rejection at position "B"

Container inspection: Contour and side wall

Rejection at position "D"

Container inspection: Side wall quality inspection/wall thickness measurement

No rejection

Container inspection: Sealing surface

Rejection at position "D"

Container base

Rejection at position "C" (lock)

Benefits to you

Excellent bottle quality

PET-View systematically rejects faulty preforms and PET bottles and thereby ensures first-class container quality.

Trouble-free blowing process

The inspection system enables only faultless preforms for blow moulding. It thereby protects the blow moulder from malfunctions and enables a smooth bottle production.

Comfortable and efficient access

The system can be completely operated via the blow moulder's touch-screen panel.