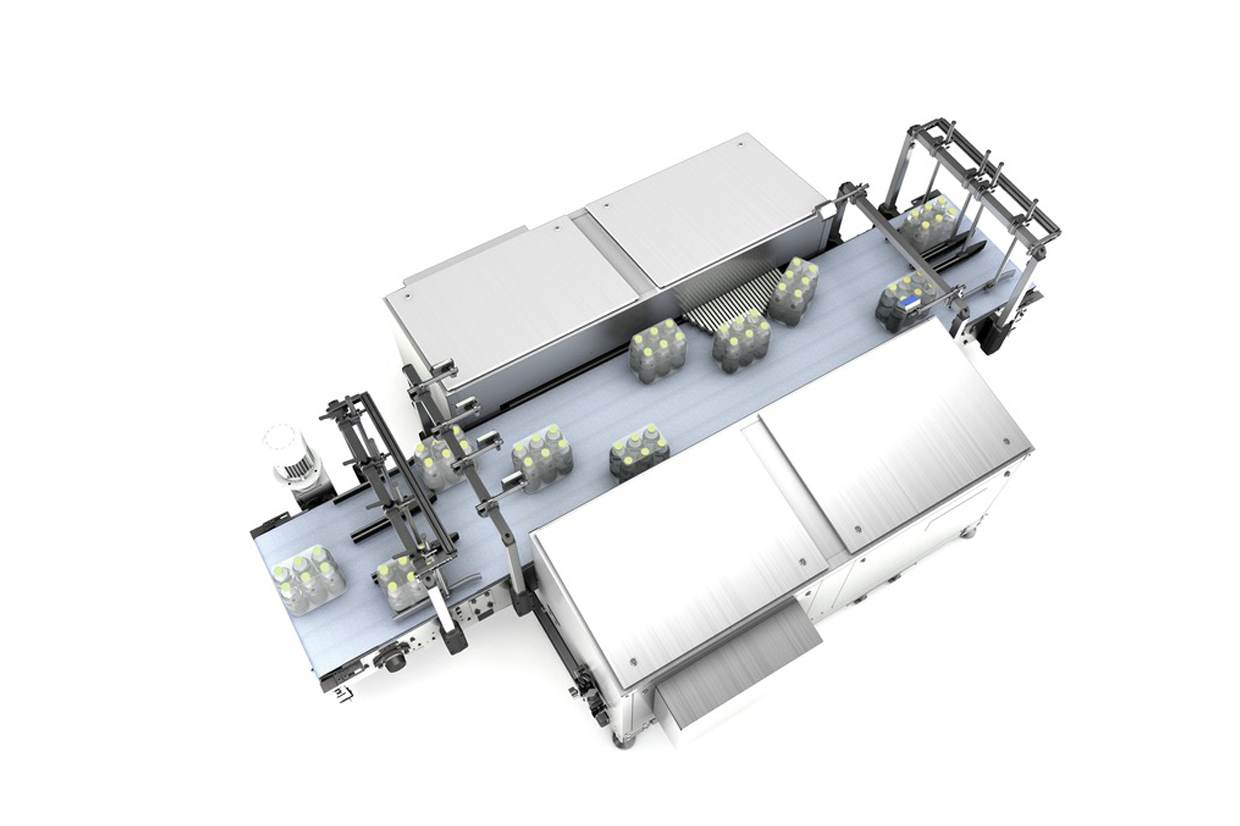

Flexible conveyor for all pack types

The achiever among conveyors

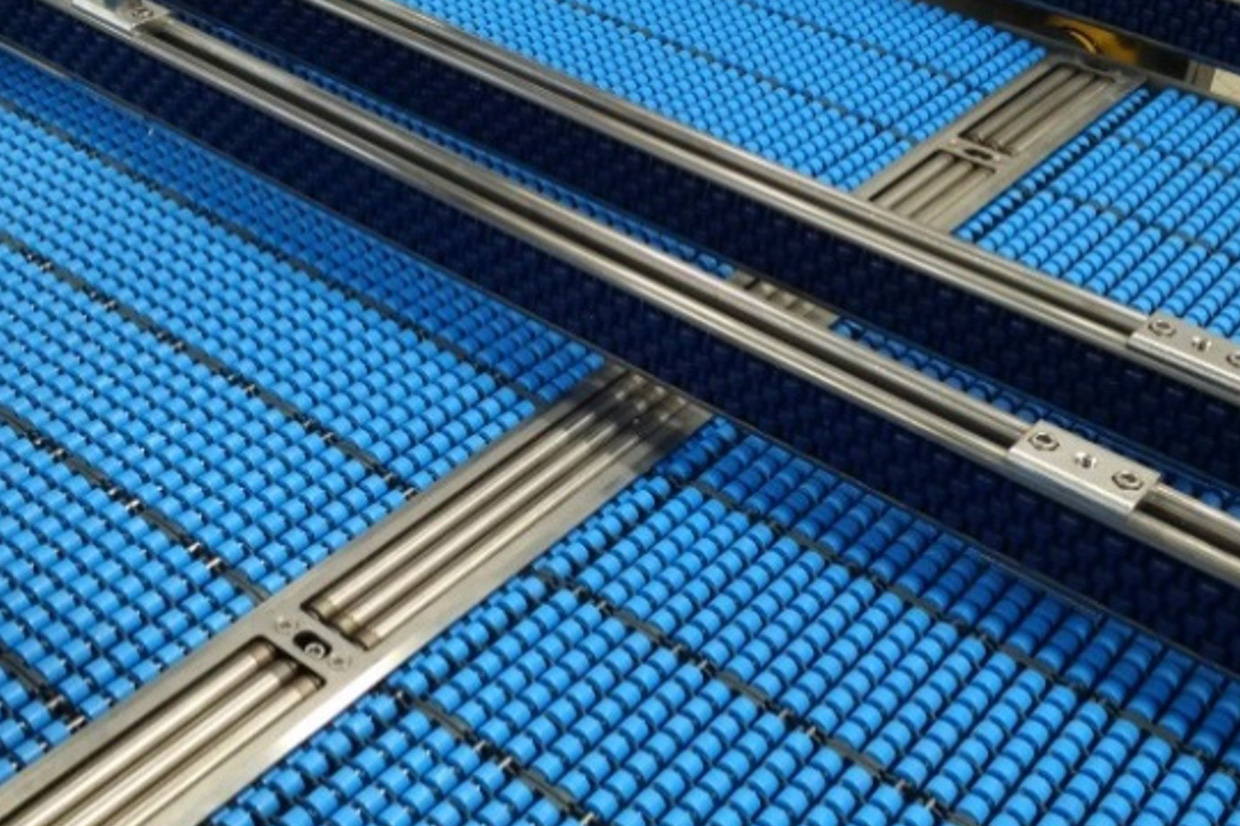

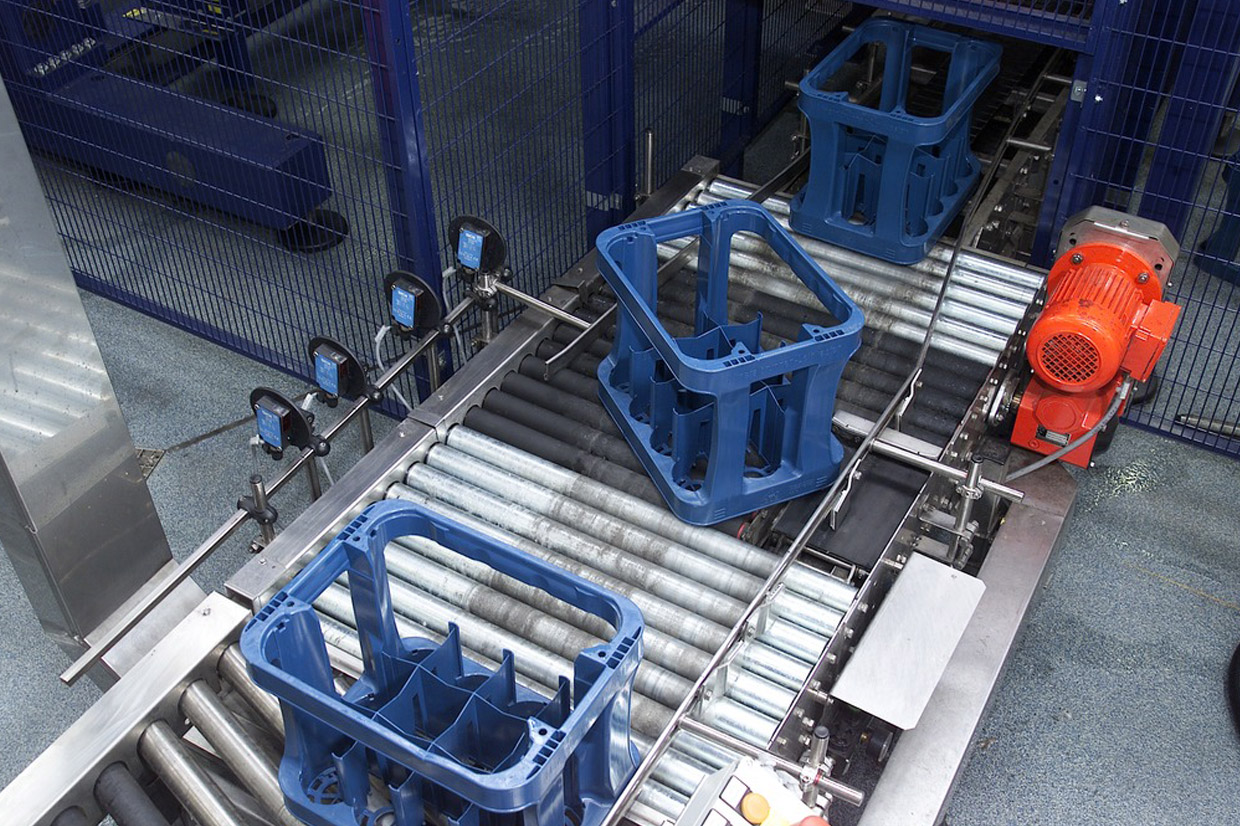

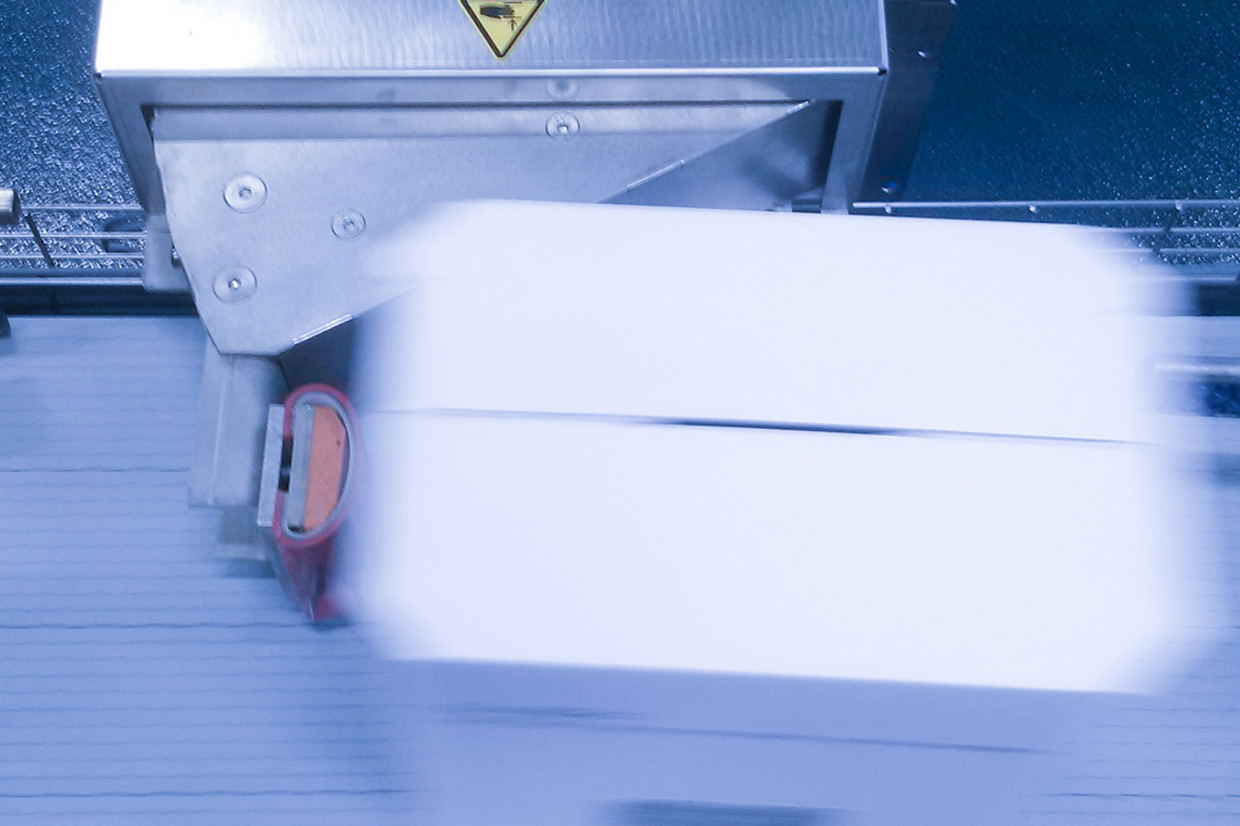

The MultiCo pack conveyor, an expert example of how to optimally link machines, proves itself to be flexible as regards the handling of different pack types and intelligent in the control of the product flow. The continuous pack flow features an optimal speed and sufficient buffer distance which is compulsory in each filling line.

Gentle product handling and low-noise operation, as well as the low energy consumption, make the MultiCo a reliable partner for your bottling line.

At a glance

- Processing of different packs such as cartons, trays, clusters, shrink packs, LitePac Top and plastic crates

- Flexible line output with frequency-controlled drives and highly precise sensors as well as intelligent control of the pack flow

- Wide range of conveyor and rejection unit variants

Technical details

Design features

- Stable stainless steel design with a panel height of 200 mm

- Height-adjustable conveyor supports

- Open design for the optimum removal of glass fragments and dirt

- Use of a wide variety of stainless steel, plastic or back-up conveyor chains possible

- Glide strips made of ultra-high molecular weight PE

- Curves in Magnetflex design

- Stainless steel support spindles with plastic foot pad

Additional equipment

- Use of commercial shaft-mounted gears

- Return shafts on bearings

- Split drive and return sprockets

- Drip pans

- Lubrication-free flat-top chain

Assemblies

Benefits to you

Quick installation and commissioning

The major part of the components is already pre-assembled at the factory. This ensures the conveyor is ready for operation quickly at the customer site in accordance with the "plug-and-play" principle.

Ease of operation

The complete system ensures ease of operation: "Directing" MultiCo is easy from a touch-screen with menu guidance and clear overall visualisation.

Short change-over times

MultiCo is flexible and allows fast change-over to other pack types with just a few simple steps.

Long service life

The sturdy basic construction ensures the long service life and problem-free operation of the conveyor.

This is why the MultiCo is enviro-certified

- Permanently excited SEW Movigear synchronous geared motor with IE5 efficiency and integrated, efficiency-optimised parallel shaft helical gear unit

- Use of enclosed lifetime-lubricated bearings

- Use of H1-greases and lubricants

- Use of a standstill circuit in the event of a pack shortage with automatic restart of the conveyors (with the non-returnables MultiCo)

- enviro option: Energy measuring package

This product is enviro classified

Top technology for ecologically efficient production

The Krones sustainability programme enviro: top technology for ecologically efficient production.