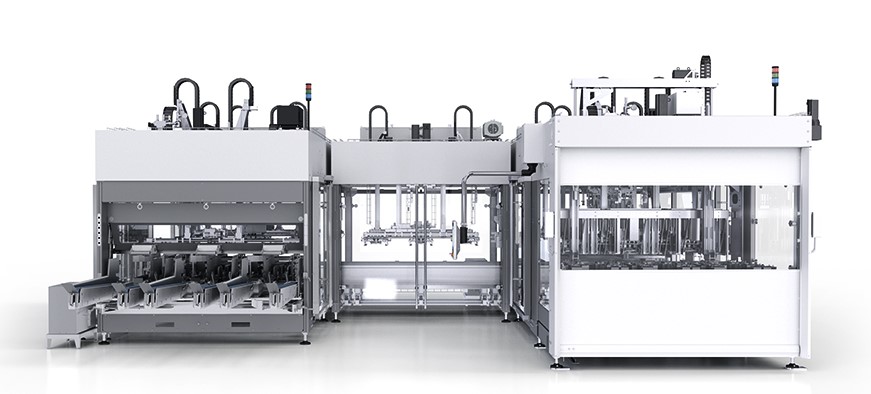

Packaging line for maximum flexibility

Maximum flexibility for secondary and tertiary packagings

The infinitely variable packaging line: KRONES Varioline. This flexible system processes more than 20 packaging combinations in one machine and therefore it meets the demands of the beverage and food producers with regards to a versatile and individual production. Since 2012, there is now a three-digit number of Varioline machines successfully in use worldwide.

At a glance:

- Flexible processing of a large number of packaging types on one machine

- Modular, customer-specific machine configuration based on the desired packaging formats

- Three different standard module types:

- Module for handling multipacks

- Module for handling carton sleeves and trays

- Universal module for different functions

- Combined handling of non-returnable and returnable packs

- High output: Up to 100,000 containers per hour – depending on the packaging type

Processing range of packaging types

There are hardly any limits to combining different packaging types on the Varioline

Three modules – numerous packaging options

Module for handling carton sleeves and trays

- Freely accessible magazine conveyors for a storage capacity of up to 4.5 metres

- Processes upright carton sleeves (RSC) or trays.

- Conventional carton erector and carton sealer integrated

Universally usable module

- Single module for special functions (e.g. orientation or sealing of packages)

- It can be equipped with a gluing unit or a separate container infeed

Module for handling multipacks

- Exchangeable carton magazine for a maximum of packaging variants in flat initial states

- Continuous container infeed usually as an integral component

Benefits to you

Combination of secondary and tertiary packagings

The Varioline combines up to six machines and it combines different returnable and non-returnable packaging variants.

Modular design

We will already define possible packaging combinations with you beforehand. This way, you will get exactly that machine from our modular Varioline component system that is tailored to your needs.

Continuous container infeed

The synchronous movement of the gripper system and the container flow significantly reduce the strain acting on the product. Thanks to its continuous movement, the infeed system enables processing of soft and glass containers without any pressure and gaps.

Everything from a single source

Krones develops and manufactures all components integrated in the packaging line. This way, all modules and components operate without any interfaces. The machine is also ideally customised for use in the dry end.

More than 100 references

The Varioline is available on the market since 2012 with great success: Hundreds of machines of this type are already in use worldwide.

This is why the Varioline is enviro-classified:

- Servo-controlled drives with IE4 energy efficiency class

- Use of fixed-mounted motors in the robot to reduce the moved mass

- Modular ACOPOS multi drive system from B&R where all the braking energy is lead back to an intermediate circuit for re-use at the acceleration process (with all drives)

- Electrical vacuum pump

- Use of enclosed lifetime-lubricated bearings

- Use of H1-greases and lubricants

- Energy measurement (optional): using an ammeter

- Energy measurement package (optional): Flow meter for compressed air consumption and leakage detection