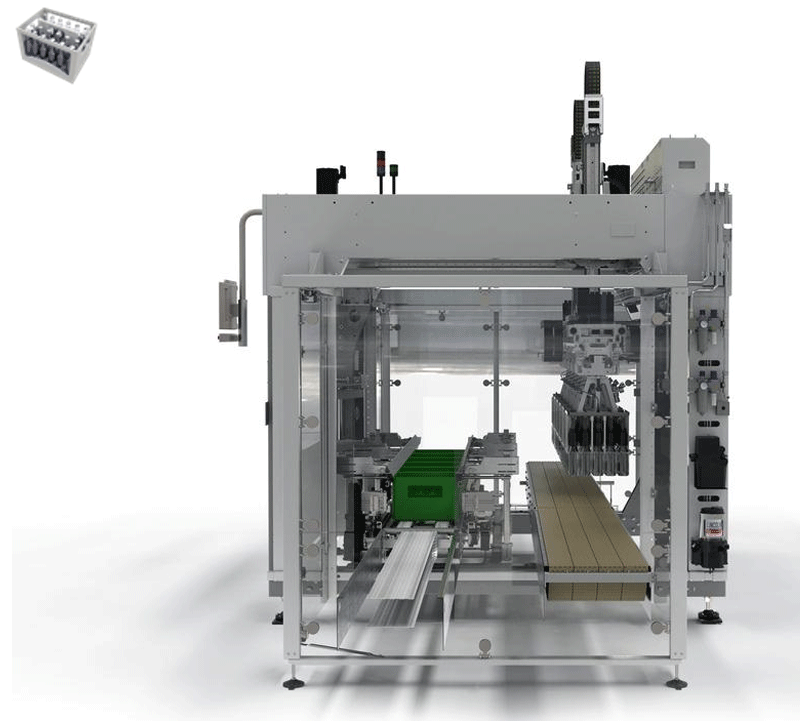

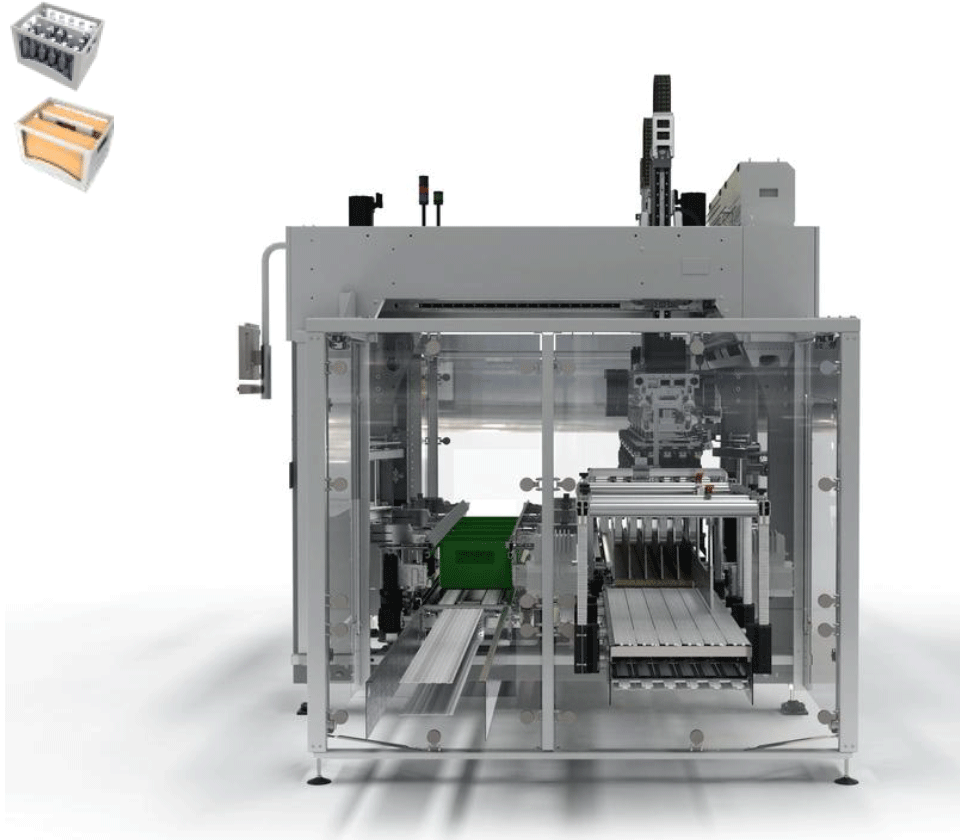

Unpacker and packer for lines for returnables

Unpacking and packing returnable containers

The Krones Varioline is known for its flexibility, because thanks to various modules, more than 20 different packaging combinations can be realised. For the field of returnable containers, Krones has developed two machine types: the Varioline U and the Varioline C for packing and unpacking returnable packs.

At a glance

- Packing glass bottles, plastic containers (PET, HDPE as well as specially-shaped container), cans or packs in crates or erected folding cartons

- Can be used both as an unpacker (type U*) as well as a packer (type C*)

- Scalable output**

- Up to 722 cycles per hour with up to 6 gripper heads

- Up to 4,332 crates per hour*

- Up to 104,000 containers per hour

- Compact and flexible layout

- Single-lane design: Dimensions depend of the pack and the output

- Can be used as both a head as well as also throughpassage machine

* U=Uncaser, C=Caser | ** Depending on the pack size and size, etc.

Variants

Unpacker for

- Empties from returnable crates

Smooth handling

- Continuous container discharge

- Continuous pack infeed (plastic crates)

- No hook stoppers/space stoppers

- Centring device in the gripper heads

Precise handling

- Well-proved packing head technology

Machine guards

- With single-head deflection

Packer for

- Loose containers in crates for returnable containers or cartons

- Multipacks in crates for returnable containers (centre sleeves) or cartons

Handling a variety of container shapes and sizes

- Pressure-optimised insertion of containers

- Product-optimised travelling curve

Gentle processing

- Continuous container infeed

- Continuous pack infeed (plastic crates)

- No hook stoppers/space stoppers

Machine guards

- With single-head deflection

Variability

- If required, the Varioline C packer can also be expanded with a carton magazine.

This is why the Varioline is enviro-classified

- Servo-controlled drives with IE4 energy efficiency class

- Use of fixed-mounted motors in the robot to reduce the moved mass

- Modular ACOPOS multi drive system from B&R where all the braking energy is lead back to an intermediate circuit for re-use at the acceleration process (with all drives)

- Energy measurement (optional): using an ammeter

- Energy measurement package (optional): Flow meter for compressed air consumption and leakage detection

- Electrical vacuum pump

- Use of enclosed lifetime-lubricated bearings

- Use of H1-greases and lubricants

Benefits

Transparency and efficiency

The Varioline covers the entire performance spectrum. Sophisticated details such as excellent accessibility, guided troubleshooting and the change-over assistant ensure high machine efficiency and ease of operation.

More peace and quiet in the returnable line

Continuous infeeds and noise-reducing machine protection mean that the Varioline is a very quiet returnable packer/unpacker (type U: < 75 dBA, type C: < 85 dBA)

Continuous container and pack infeed

The synchronous movement of the gripper system and the container flow significantly reduce the strain acting on the container. Thanks to its continuous movement, the infeed system enables processing of soft and glass containers without any pressure and gaps.The continuous container infeed eliminates the usual stoppers and enables a smooth container infeed.

More flexibility in planning

The infeeds and discharge of the Varioline can be flexibly arranged so that both through-passage and head machines are possible. In conjunction with the compact footprint, the Varioline is also a good choice for retrofitting.

More than 100 references

The Varioline is available on the market since 2012 with great success: A three-digit number of Varioline machines are already in use worldwide. Since 2018, the Varioline has also been used purely as a packer for returnables.