Keeping a lid on it

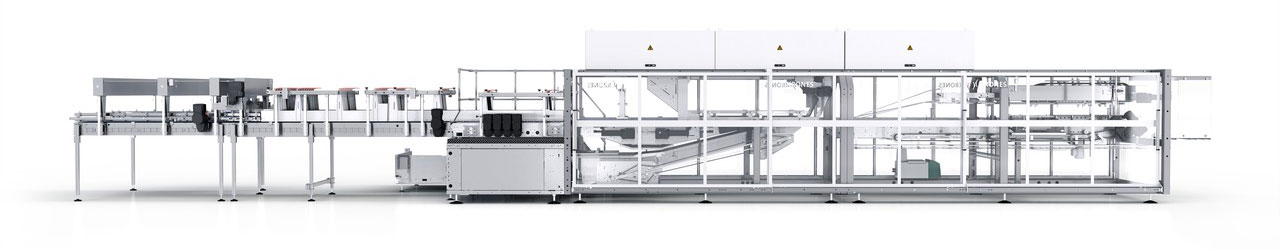

It is the perfect accompaniment for packers: The Checkmat 725 keeps a very close eye on the cartons while they are being glued. It checks if enough glue has been applied – and thus ensures that the cartons are securely closed when then they reach the retail market.

At a glance

- Direct integration in the lead machine

- Verification with a camera system

- 99,9 % detection of consecutive faults

Splicing point detection integrated in the lead machine

| Inspection of the closed cartons for | max. packs per min |

|---|---|

| the application of hotmelt via temperature measurement | 120 |

| the number of glue beads | 57 |

| the length and width of the glue beads | 57 |

Technical features

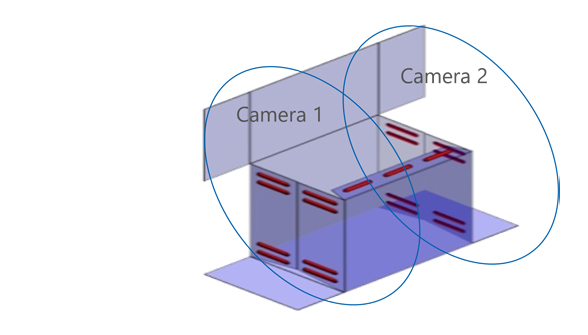

- 2 infrared cameras

- Output: max. 57 or 120 packs per min*

- Max. conveyor speed 0.5 m/s or 1 m/s *

- Visualisation system in the lead machine

- No rejection system provided

- 99.9 % detection of consecutive faults

Variopac Pro W/WT/WTS

Splicing point detection

Method of operation

- W = wrap-around packaging

- WT = wrap-around and tray packaging

- WTS = wrap-around, tray and tray-shrink packaging

Range of applications

Adjustments at the lead machine type Variopac Pro W/WT/WTS:

- The lengths of the glue beads can be adjusted on the touch-screen.

- Glue beads can be interrupted, depending on the format.

- Spot application and line application are possible.

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events