Both labs are located in Regensburg’s TechBase. And both have made it their mission to take up current trends and, in interdisciplinary teams, use them to develop solutions that are both visionary and practicable. But what sort of trends are we talking about? How far are we looking into the future? And what does interdisciplinary work look like in practice? In this article, we’ll answer those questions – with real-life examples.

A psychologist, a business major, and an IT guy walk into a room... No, this isn’t the start of a joke. It’s what actually happens when students from very different disciplines come together in Krones’ Innovation Lab and Design Lab to work on the innovations of the future.

The Innovation Lab: incubating ideas in a start-up atmosphere

The Innovation Lab was established in October 2016 and is part of Krones’ Corporate Research and Development (CRD) business area. Its mission is to study and evaluate new technologies through feasibility studies and proofs of concept and to use rapid prototyping to implement projects in the fields of digital transformation and Industry 4.0. What makes this concept special is that the team consists not of engineers and other technical experts but rather of students from a wide range of different fields and levels of experience. “We’ve got it all, from interns to student trainees to students who are writing their final theses. It’s really a mix of business, technical fields, and IT,” explains Sina Stieglmeier, who heads the Innovation Lab. “As a result, we get ideas coming from very diverse perspectives.”

The students work in small teams, in a casual start-up-style atmosphere, to transform innovative ideas into practicable solutions. The goal is ultimately to get fast, well-conceived results. Project planning is usually done rather spontaneously, because each project has a turnaround time of just five to six months. And the ideas come from throughout the entire company. All Krones employees can submit suggestions to the Innovation Lab. Ideas are selected for further development based on feasibility – because not every idea is well suited for this type of implementation. Projects may be related to internal processes as well as innovations for customers.

Real-life examples

The making of AI Explorer

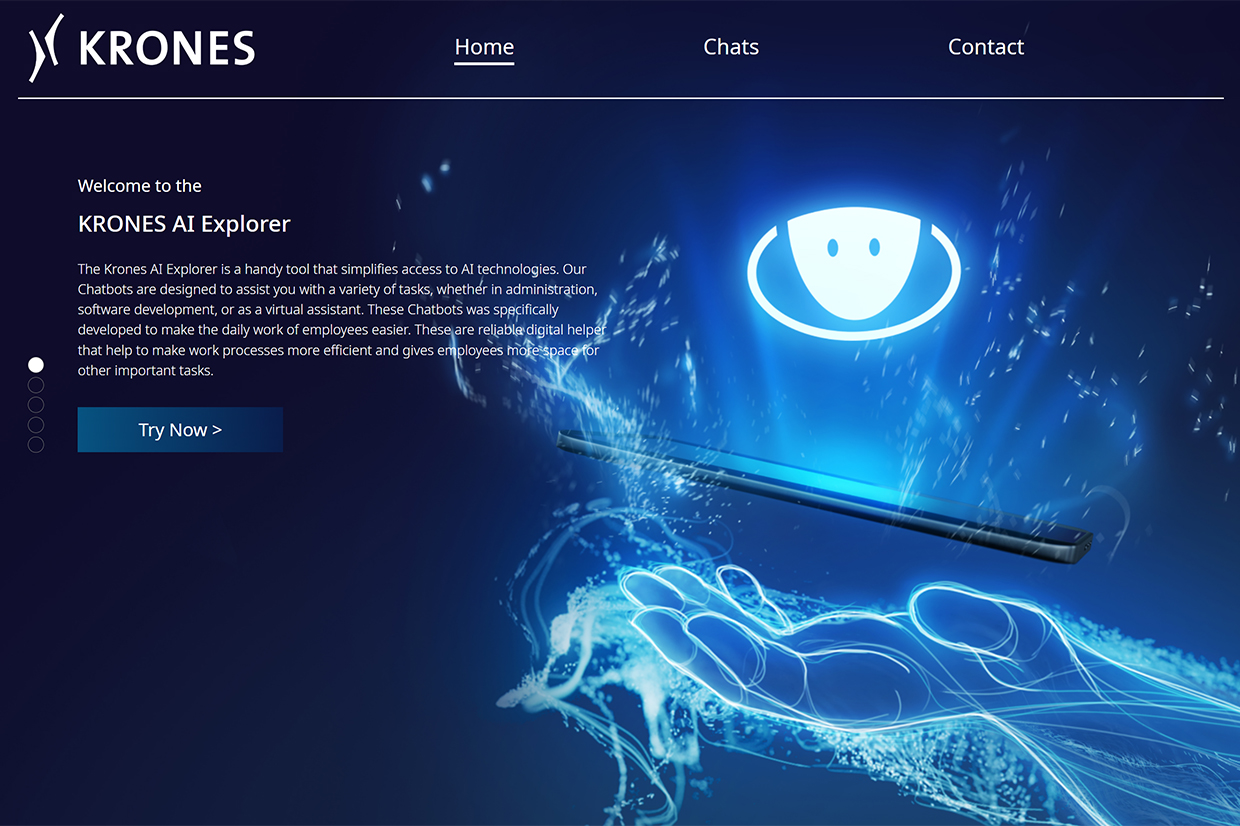

One obvious topic for the Innovation Lab is artificial intelligence (AI). The lab’s current objective here is twofold: to establish a central hub for Krones employees to find AI solutions within the company and to develop a chatbot alternative to ChatGPT for the entire group to use internally.

The Krones AI Explorer was a real success story: Three students took the lead on this project, and in just five months’ time the team had accomplished both objectives, building a fully functional web application that serves as a hub for AI solutions and launching the “Coby” chatbot. That was possible thanks in large part to how efficiently the three teammates – an AI person, a computer scientist and a business administration student – had divided up their workload:

- The AI specialist focused on ensuring the chatbot’s context sensitivity and tuning the language model so that Coby can recognize references between messages. Besides programming the app itself – a task for which his IT partner supplied valuable input – the AI guy also took care of all aspects of preparing the data for the test phase of both projects.

- Meanwhile, the IT guy used his computer science savvy and the support of the Information Management department to tie the backend of both applications into Krones’ existing IT structure.

- The business management student took care of all the administrative tasks – from clarifying data protection matters with the Works Council to informing test users right through to the organizational side (that is, the project management proper). He even created a mockup of the app’s layout. As a lay person, which isn’t usually involved in app development, he studied up on the topic and was able to play a crucial role in designing the apps.

Following a pilot phase that extended over multiple months, the apps were rolled out across the company in early June. Since then, both the platform and the chatbot have been available to all Krones employees. Sina Stieglmeier puts it in a nutshell: “I’m very proud that our small team was able to accomplish this huge project in such a very short time. The fact that our apps have now been rolled out across the entire company is a testament to the team’s success. Normally, we only develop prototypes and then pass the knowledge we collect back to Krones. With the AI Explorer and the Coby chatbot, though, we’ve implemented a product with nearly everything ready for use. It’s incredibly gratifying!”

Innovations in systems technology

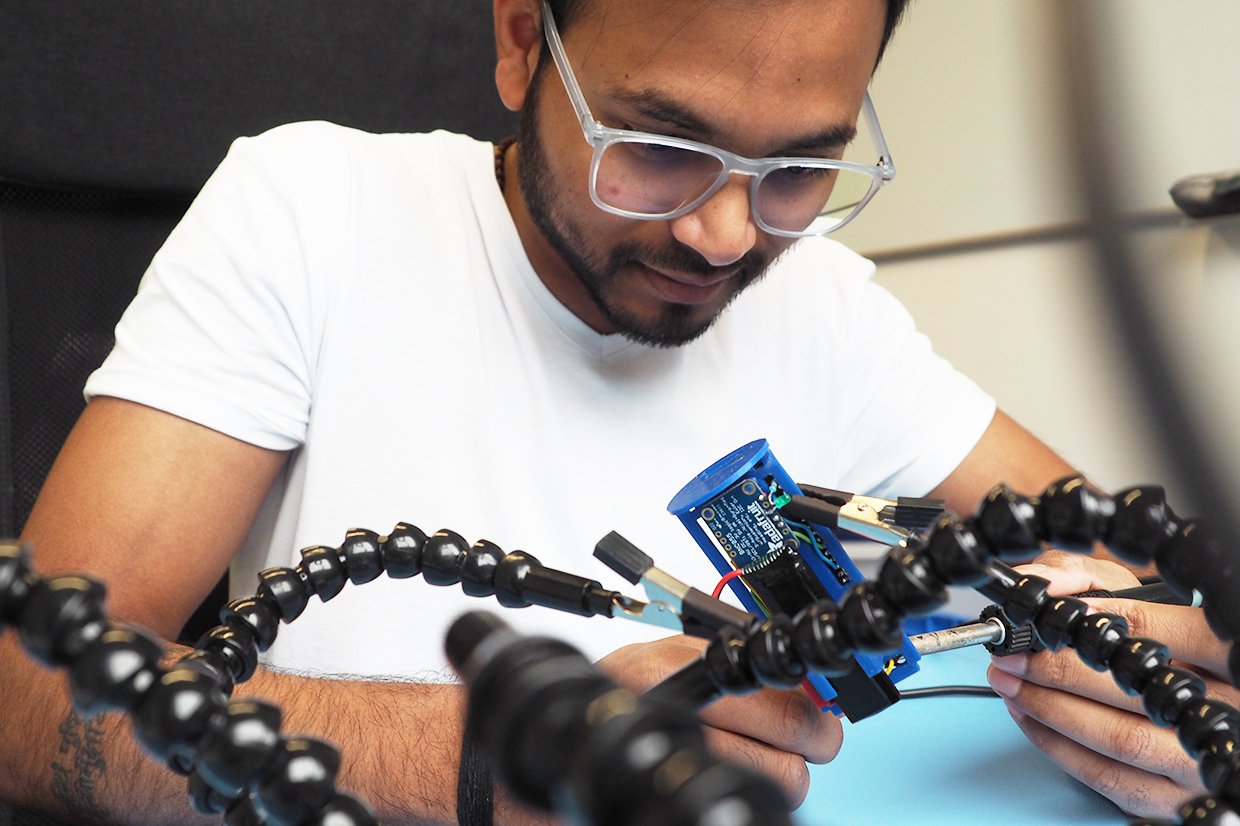

Another Innovation Lab project began in the development team for filling technology, who approached the think tank with the following problem: In many industrial systems, rotating nozzles are used for cleaning. But sometimes a nozzle will stop rotating and, as a result, the system can no longer be cleaned optimally. Right now, nozzle rotation is monitored manually, by the operator. The Innovation Lab is currently working on an automated solution based on the principle of energy harvesting.

Corresponding prototypes are currently under development. For Sina Stieglmeier, the project has all the energy of a start-up: “The students and I have been having a lot of fun tinkering and puzzling over this. It’s incredibly motivating to take a prototype from an initial concept on paper to a physical component – especially when it also ends up working.”

The Design Lab: the creative side of human-machine interaction

The second pillar of development at Krones when it comes to new trends is the Design Lab, which was established in April 2024. This new team of creatives under the direction of Christian Colceriu concentrates on supporting existing development projects at Krones with respect to human-centered design. The goal is to ensure that newly developed machines and systems meet the needs of their users and that operating them feels intuitive, while at the same time making sure they represent the corporate design of the Krones brand.

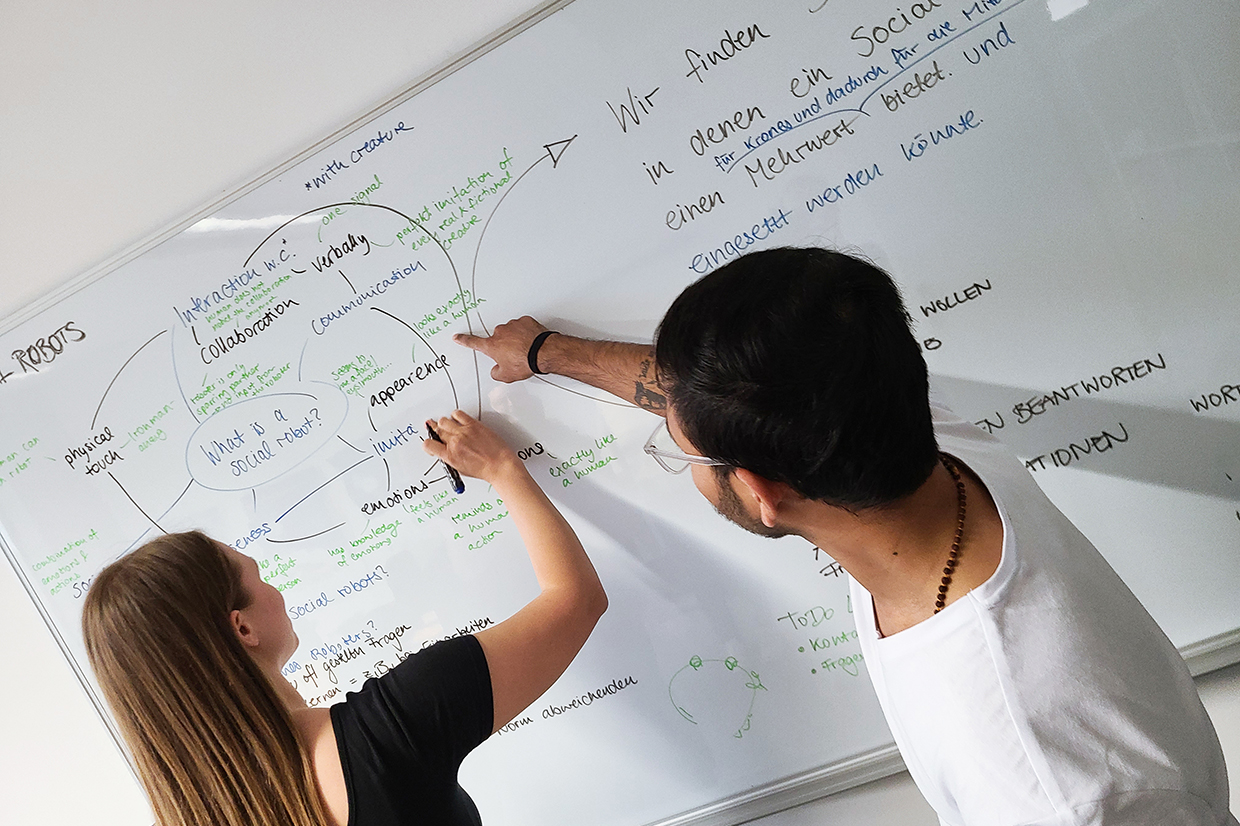

To achieve this, the team uses methods and expertise from industrial design and cognitive psychology, which is why the team is made up primarily of students in these disciplines. “Creativity is all about sharing ideas,” explains Christian Colceriu. “Just like in any other design think tank, the team regularly meets in small groups or workshops – which is why the Design Lab offers many options for sharing, such as entire whiteboard walls, comfortable seating areas and workshop spaces. We’ve got room enough here to leave our sketches and notes on the walls for days on end until that eureka moment hits.” The projects, which are initiated by Krones CRD and Krones.digital, can vary widely in both scope and duration – from a week to a year, anything is possible.

[...] Whiteboard walls, comfortable seating areas and workshop spaces. We’ve got room enough here to leave our sketches and notes on the walls for days on end until that eureka moment hits.

Christian ColceriuHead of Design Lab

Christian ColceriuHead of Design Lab

Real-life examples

Robotics from a designer’s perspective

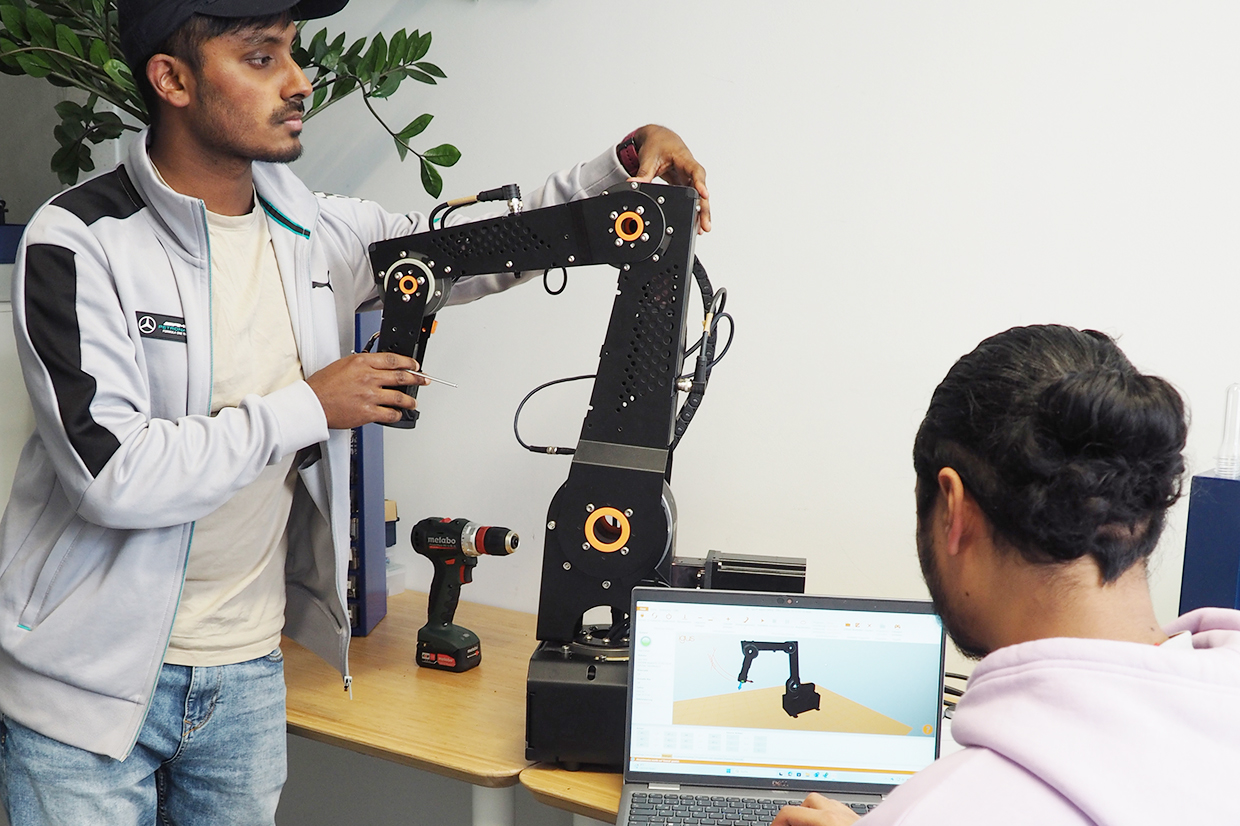

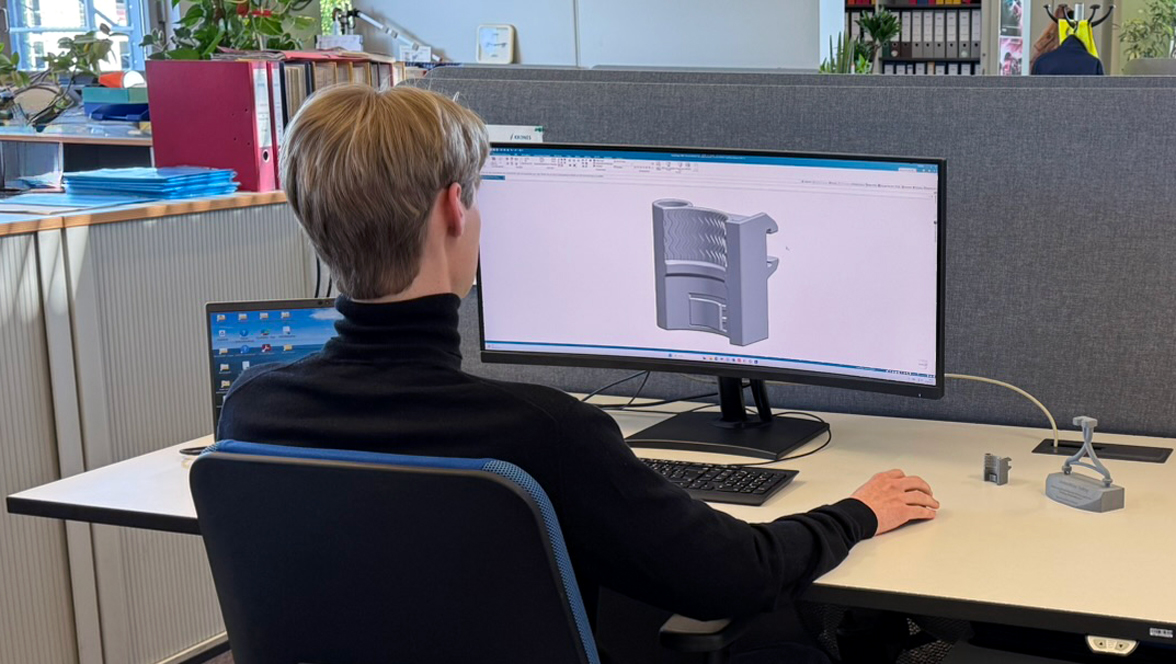

Although the Design Lab is still very young, it’s already deeply involved in the innovation process. One project that has been completed successfully was in cooperation with Krones’ Mobile Production Robotics (MPR) team. In it, the design team received 3D drawings for a mobile robot system for production. The team used the drawings to generate a visualization and then a concrete machine design.

In the process, they had to take a number of criteria into account: “On the one hand, it should be easily recognizable that the robot is from Krones – so, of course, the design had to be attractive. We worked very closely with Corporate Communications on that. At the same time, it had to be space efficient and free of any sharp edges. Putting that all into practice while staying within budget was a challenge, but we did it,” explains Christian Colceriu with visible pride.

Once an initial visualization concept had been developed to the team’s satisfaction, meeting all the challenging criteria, the students took a closer look at it in the virtual reality (VR) space. Using VR, they were able to identify where additional fine tuning was needed in order to have a truly well-thought-out product in the end that makes the production of a Krones line even more efficient.

By the way, did you know...?

Krones received the coveted German Design Award in the category Excellent Product Design Industry for its mobile robot system Mobile Production Robotics (MPR). The system supports Krones' clients in supplying materials to filling and packaging lines. It also helps to reduce operating costs and make production even more flexible. The robot’s integrative, uncluttered design meets the standards for the food industry.

Sustainability in action

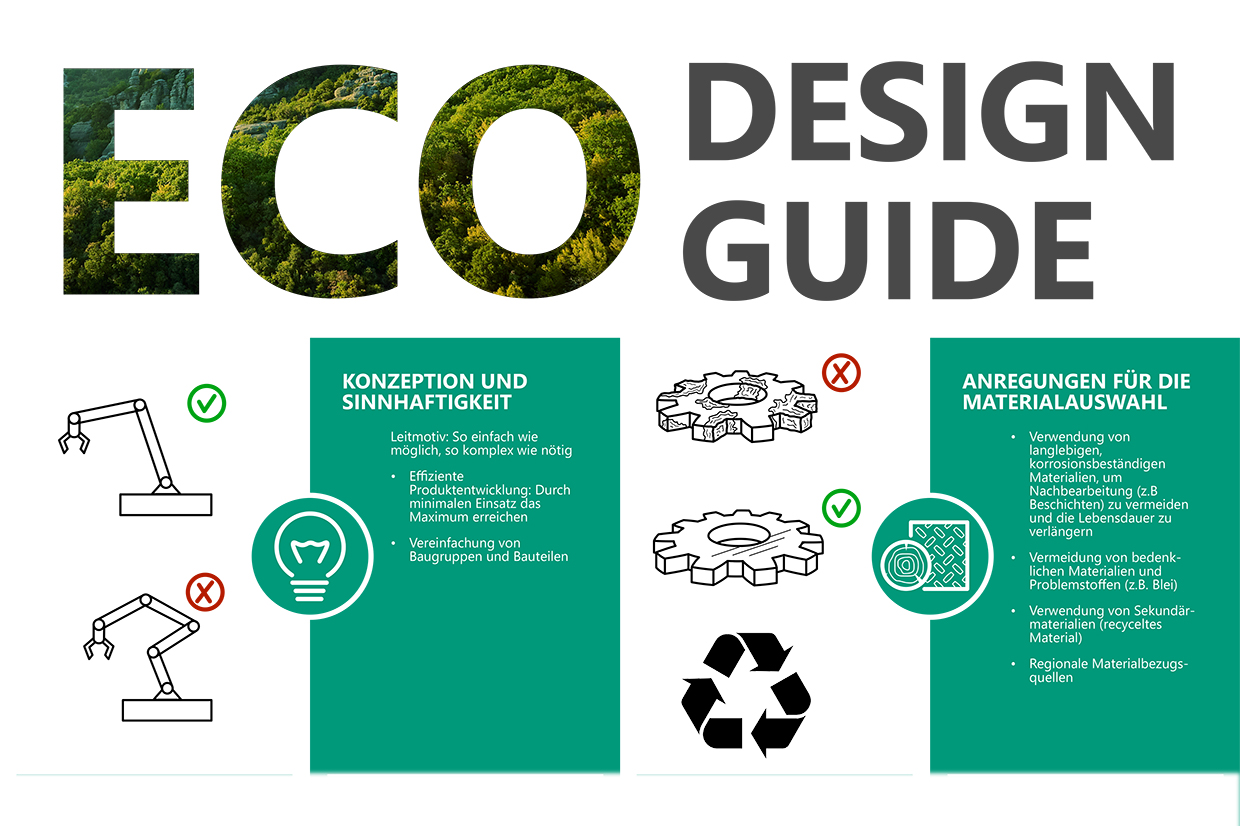

The Design Lab also seeks to answer the question, “How can design contribute to sustainability within our business?” What started with a senior thesis will in future be applied throughout the entire company: The Design Lab team is working on a set of instructions for design that will go by the title “Eco Design Guide”. The guide is intended to bridge the gap between abstract sustainability concepts and precise recommendations for action.

To start with, the team gathered input from design engineers on possible sustainability potential. That was followed by the resulting suggestions being tested for meaningfulness and feasibility. The Eco Design Guide was then created – with eye-catching text and images – in coordination with the sustainability department. Colceriu describes it this way: “The guide will help the project team make sustainable decisions for products throughout their development.”

As part of another thesis project, the team is now applying the principles of the Eco Design Guide, to the production robot mentioned earlier – with the aim of deriving precise design recommendations for it. This will also help to determine whether the guide can be applied to the future development of certain products.

Conclusion

“We encourage unconventional thinkers to drive innovation and our business." That is part of our corporate vision and mission. And even though we can’t see into the future, we can say this with considerable certainty: the continued development of new trends and innovations isn’t going to stop. On the contrary, it’s only going to become more important. That’s a future that both the Innovation Lab and the Design Lab are perfectly prepared to face thanks to their visionary, creative spirit.