Ingenuity for the cold section

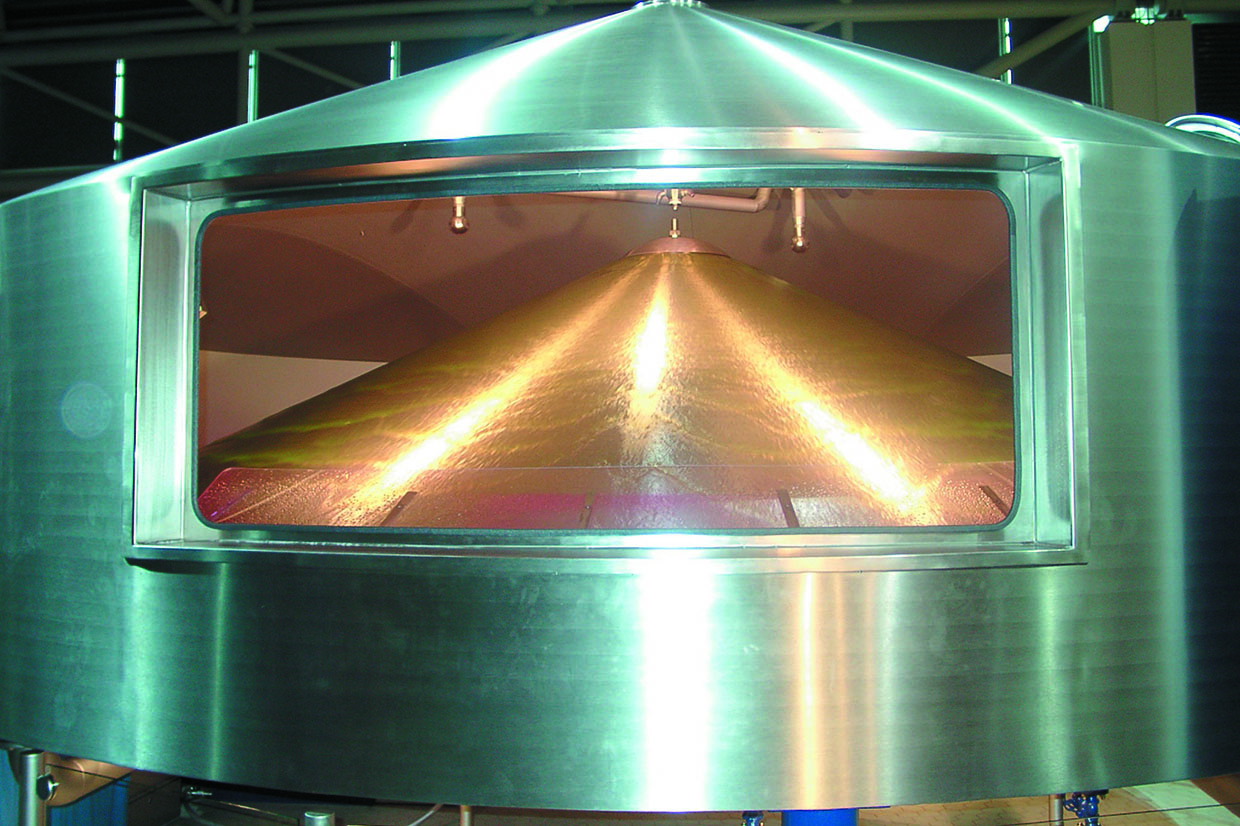

In 2008, Steinecker resumed the construction of large tanks. Since then, tanks of any kind with diameters of up to 4.25 metres and overall heights of 9 metres have in their entirety been manufactured in the Steinecker plant, with specimens bigger than that being completed on site.

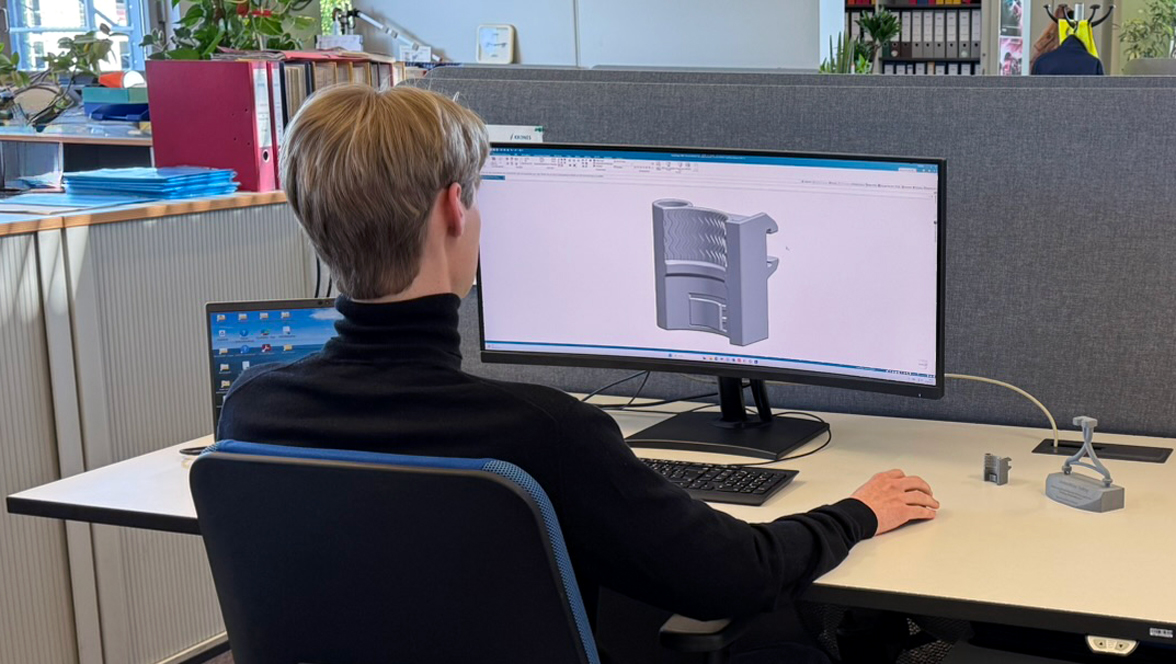

In 2009, Steinecker introduced TwinPro, a new fully automated concept for the cellar pipe system. It can be expanded as needed and is based on two valve blocks, one for filling the tanks and one for draining them, which are linked to each other by a bypass. Up to four tanks can be grouped together in a tank loop, which makes for substantially shorter pipe lengths and concomitantly lower investment and operating costs. The same year saw the development of the route management system DynaRoute, a software that uses a set of predefined criteria for automatically finding the most suitable route for the product handled in each case.

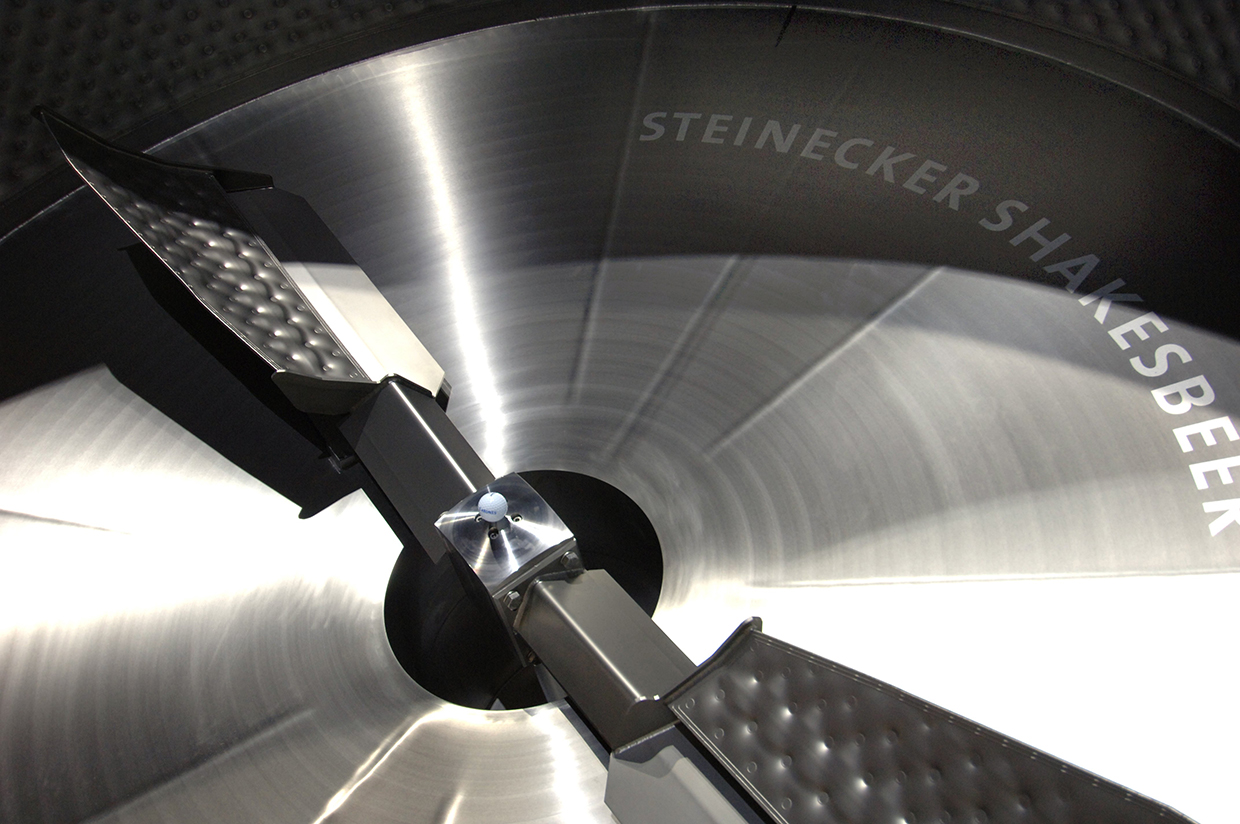

Poseidon gets things moving in the tank

The Poseidon system for recirculating beer in the tank was launched in 2017. Thanks to three inlet and outlet ports fitted at different heights in the tank’s centre, the circulation flows can be selectively adjusted, thus establishing various circulation zones within the tank. For example, it is possible to blend the tank’s entire contents into a homogeneous mixture during fermentation or to create a relatively calm sedimentation zone in the tank’s lower section during yeast harvesting. Poseidon was originally developed to speed up fermentation, but it also supports green-beer cooling and is frequently used for dry-hopping as well.

The technology is also particularly well suited for breweries that work with crabtree-negative yeasts for making their non-alcoholic beers and therefore have to aerate the tank under controlled conditions. Poseidon can likewise be found in bioreactors, like those used for producing alternative proteins, instead of an agitator. In short: The unit, which can easily be retrofitted through the tank opening, has become a fast-seller.