New line and energy concepts thanks to revolutionary filling and capping technology

Think differently – and revolutionize the beer filling process

Revolutionary filling technology as part of a resource-saving brewery of the future. Released cooling energy that can be used intelligently in another area. A reduced microbiological risk during filling. Last but not least: Filling and capping in a single unit, in less than five seconds, and this at ambient temperatures. When it comes to the Dynafill, the list of true unique selling points is long –and it soon becomes clear: This machine makes it possible to achieve completely new energy and line concepts.

At a glance

- Combined filling and capping process on one single machine

- Maximum speed: 80,000 containers per hour

- The Dynafill enables the following:

- Filling temperatures of up to 30 °C

- Reduced energy requirement in the entire line

- Innovative line concepts

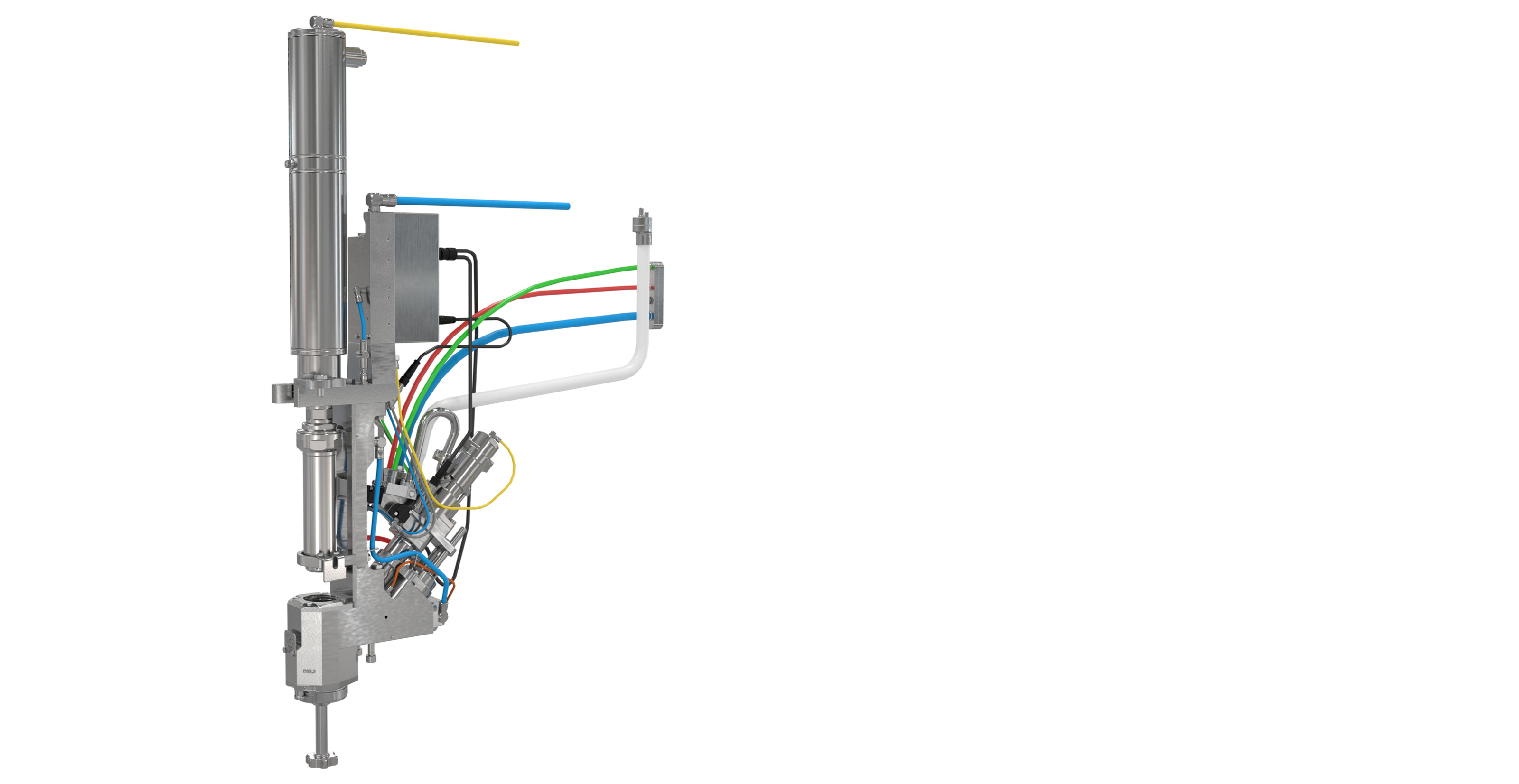

Filling and capping head

Filling and capping in one functional unit: what started out approximately ten years ago as a vision became reality in 2017 with the presentation of the first ever machine at the drinktec. Krones has since taken the Dynafillto series maturity, tested it in the field under the most diverse conditions and then further developed it based on the valuable feedback of experienced bottling companies.

Also: dismantling device for user-friendly maintenance

Manually inserted CIP cup

Bottle neck seal for handing a variety of formats

Decentrally arranged pilot valves

Servo capper for standard and twist-off crowns

Filling valve that can be moved in a diagonal direction

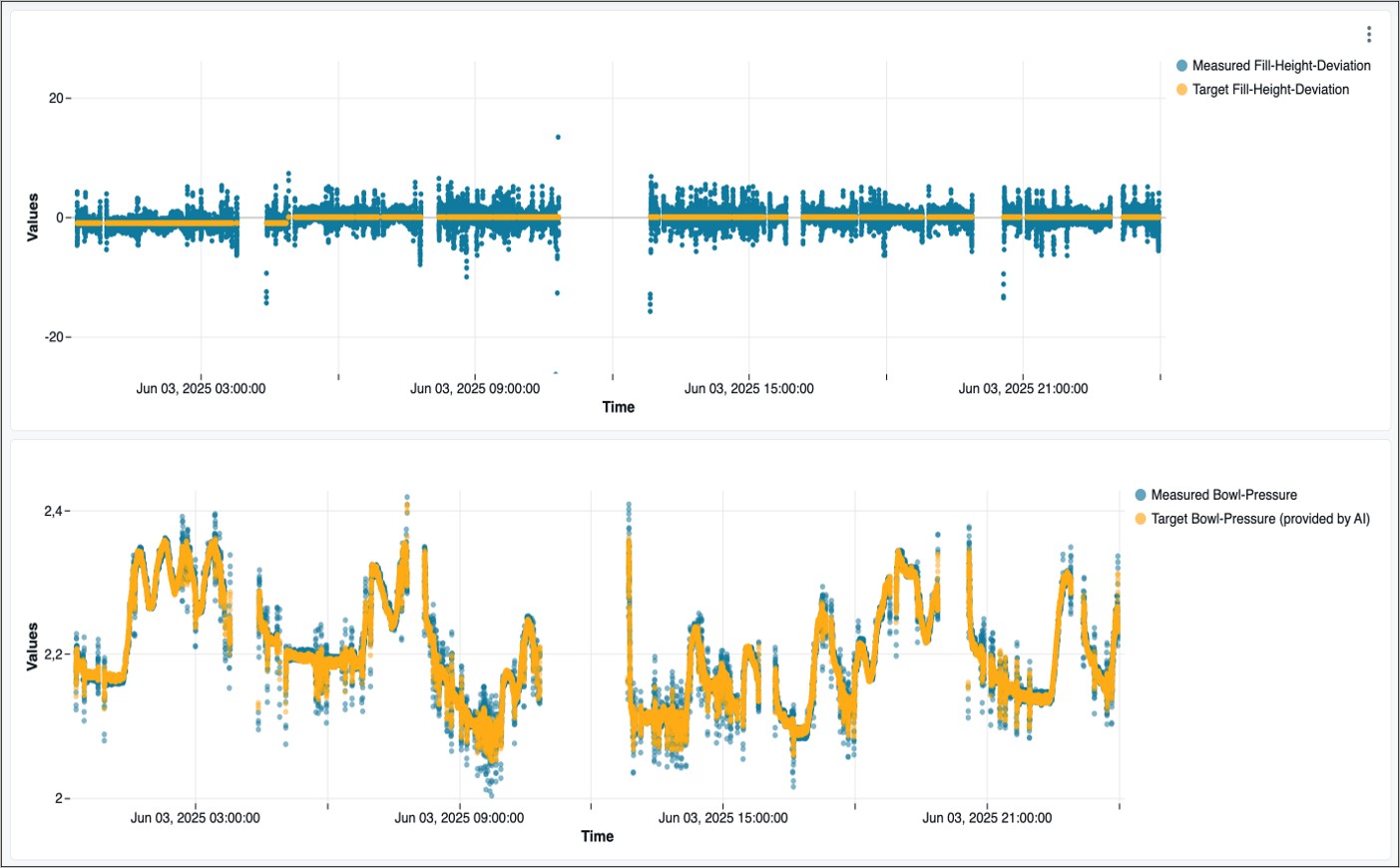

Dynafill AI

Utmost precision is required in the filling process to ensure consistently high product quality. As the fill level can only be controlled via the bowl pressure, manual readjustment by the operating personnel was previously necessary - which involved a great deal of effort and often high reject rates. With Dynafill AI, this is a thing of the past: The intelligent control system adjusts the boiler pressure fully automatically, quickly and precisely - even with fluctuating product parameters such as temperature or CO₂ content. This means that the optimum filling level is reliably achieved at all times - without any manual intervention.

At a glance

- Combination of hardware and software: AI-based control enables precise, automatic adjustment of the filling pressure.

- Use during operation: Dynafill AI measures the continuously relevant product parameters and readjusts the filling pressure if necessary.

- For major changes or if the system is changed over to new product types: The system is retrained via the Krones IIoT platform and thus learns how to adjust the filling pressure precisely to the correct fill level under the new conditions.

- The system reduces waste, saves energy and raw materials - and takes the strain off operating personnel.

- Winner of the Business Intelligence Group's AI Excellence Award 2024 in the "Intelligent Control" category

- Sensors and data acquisition: Temperature, product and CO₂ sensors as well as a camera for fill level measurement.

- Data processing and modelling: The recorded data is transferred to an edge device and stored in the Krones IIoT platform. There, a machine learning model learns the complex relationships between process parameters and the fill level.

- Model training and provision: The trained model is fed back to the edge device, where it controls the boiler pressure in real time based on current sensor data and the measured fill levels.

- Real-time control and reaction speed: The system reacts at lightning speed to changes - even during the start-up process - and keeps the fill level stable.

- Scalability and transfer: The system is designed so that it can be flexibly transferred to different products, bottle types and systems - even under changing production conditions.

- Optimisation: All measurement and control data is continuously analysed in order to further improve the model.

Saving option

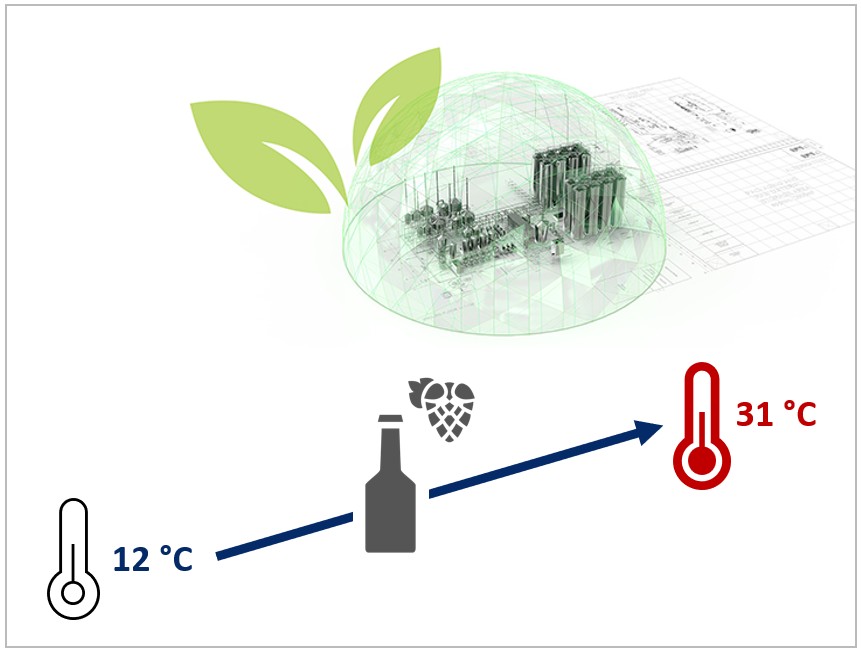

Filling and outside temperature: There is often a large difference between these two parameters in breweries. As a result, condensation forms after the filling process, and energy-intensive drying is needed to achieve trouble-free container labelling.

With the Dynafill, the filling temperature can now be continuously adjusted to fluctuating external conditions.

With the Dynafill, it is possible to continuously adjust filling temperatures between just above zero and up to around 31 degrees Celsius.

With the Dynafill, it is possible to continuously adjust filling temperatures between just above zero and up to around 31 degrees Celsius.

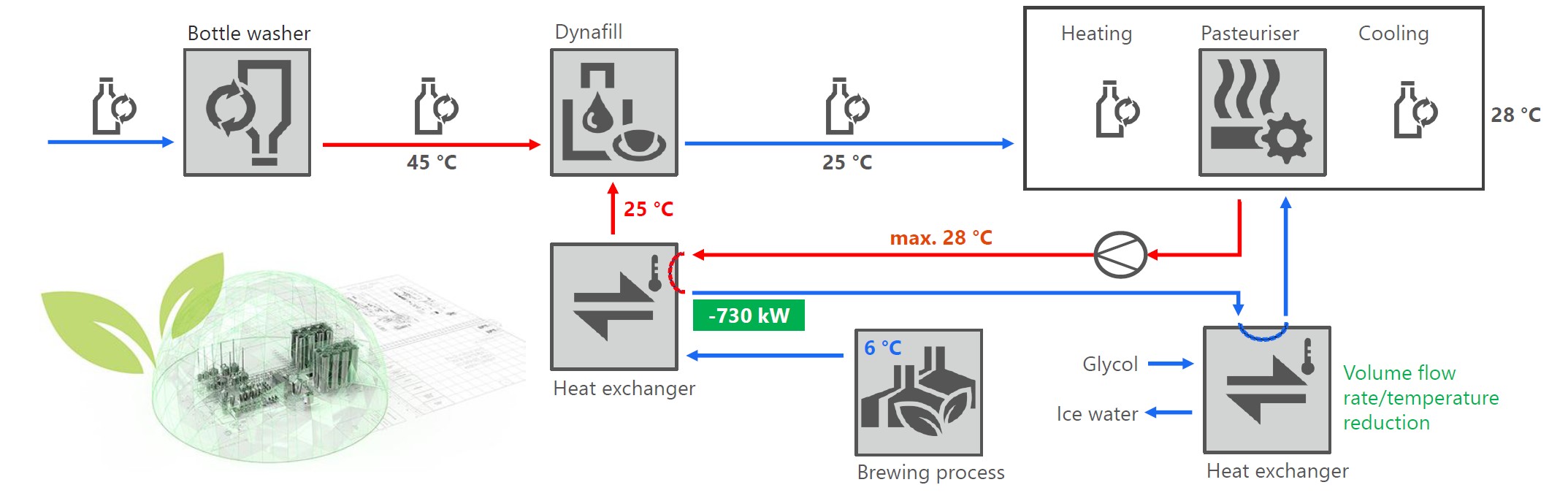

Krones conceptualises its machines as part of the bigger picture, meaning: We not only focus on the individual machine but incorporate it in overall concepts. When it comes to the Dynafill, this means: We are aware of the opportunities that warm filling offers for saving energy. We have thus developed a holistic concept where cooling energy can be recycled in other areas of the brewing or filling process.

From the retrofitting of an individual machine to the implementation of a comprehensive line concept or even the installation of a complete brewery – the benefits and thus the potential savings for a company can add up depending on the extent of changes made.

Benefits to you

Innovative line and block synchronisation concepts

In future, the Dynafill enables a higher total line output than conventional systems: Up to 80,000 containers per hour can be handled as the Dynafill principle allows for completely new planning approaches: from the elimination of accumulation and emptying sections through to the merging of a previously required double line.

Reduced space requirement

Thanks to the 2-in-1 principle, the Dynafill requires substantially less space than comparable combined filler-capper units. As the filler is not to be emptied in the case of a malfunction in the filling line, the buffer section to the labeller can be reduced. The labeller can now also be directly block synchronised with the filler, this block is already available from a filler pitch of 87 millimetres.

Process adjustments in real time

The intelligent control system in the Dynafill AI adjusts the boiler pressure fully automatically, quickly and precisely - even with fluctuating product parameters such as temperature or CO₂ content. This means that the optimum filling level is reliably achieved at all times - without any manual intervention.

Filling at ambient temperature

The Dynafill enables not only cold but also warm filling of beverages (temperatures up to 30 °C) – the process does not take longer than five seconds in both cases. The filling process remains always stable. The higher filling temperature means brewery energy concepts can be completely reinvented: depending on the line configuration, the bottle washer or even the tunnel pasteuriser can now also be included in the energy recovery system.

Increased filling quality

The closed hygienic filling and capping area ensures optimum product purity, as return gas feed back into the product bowl is no longer required. High-pressure injection is no longer required and no product is lost during filling.