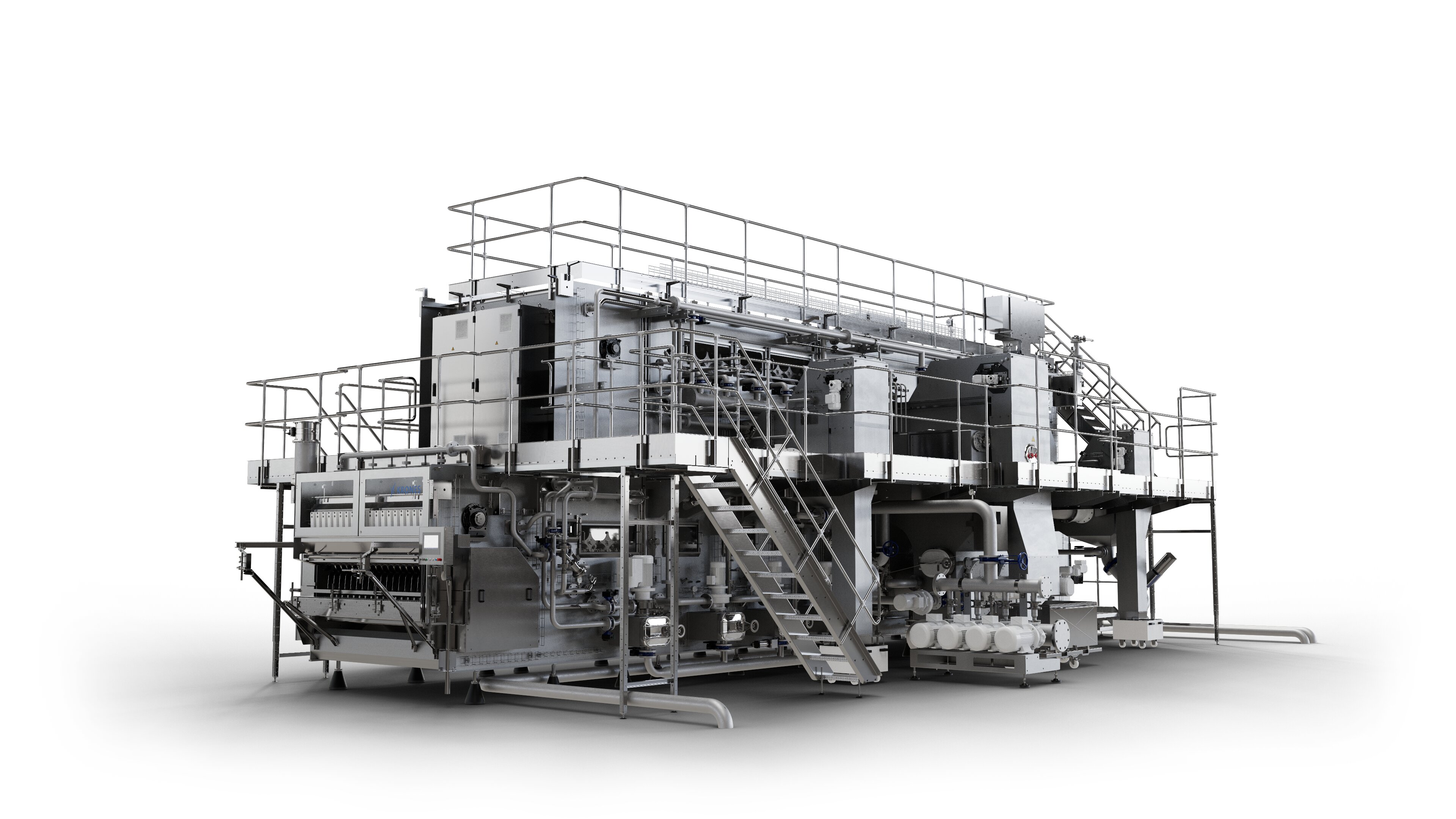

The next generation of bottle washers

Lavasonic with High Intensity (HI) module

CO2 footprint, costs for thermal energy and fresh water consumption are increasingly more relevant and cause rising costs. With new technology and innovative developments, the Lavasonic HI impresses with perfect cleaning results while using resources as economically as possible.

At a glance

- Ultrasonic technology enables shorter label removal times and faster removal of dirt

- Shorter contact time between labels and caustic

- Reduced colour particle contamination in the caustic

- Reduced energy and media consumption

- Cleaning programs tailored to requirements

- Process optimisation thanks to latest digital products

- Optimum accessibility

Highly-efficient cleaning

The key components

Controllable high-intensity cleaning

Highly-efficient cleaning:

- Cleaning time reduced by up to 40 %

- Thermal energy consumption reduced by up to 30 %

- Fresh water consumption reduced by up to 20 %

- Need-oriented jetting pressure

- Ultrasonic intensity can be adjusted as needed

- CO2 footprint reduced by up to 35 %

- Mechanical stress on containers reduced by up to 50 %

Clean Unit Control

Returned bottles are not all equally dirty. With constant machine performance, only the use of chemicals and temperature can be adjusted. With Lavasonic HI, the mechanical influence can also be controlled. This is the decisive advantage of adjusting the cleaning performance and reducing resource consumption.

Post-caustic surge system

Optional: Clean Design jetting system

Fresh water jetting is the final rinsing step before the bottle leaves the bottle washer. For even greater microbiological safety, fresh water jetting is optionally available in Clean Design.

New main caustic module

Ultrasonic effect

Ultrasound generates positive and negative pressure in the pre-soak tank. Negative pressure creates bubbles which collapse when positive pressure is applied, a process known as cavitation. This is how ultrasonic technology removes dirt and perforates paper labels. This increases the capillary forces, allowing the caustic to penetrate the paper label more quickly and thus remove it faster.

Bottle lock

The newly developed locking mechanism for returnable glass bottles enables more intensive cleaning in a shorter treatment time. Nevertheless, the bottles are subjected to less stress. The gentle treatment of the glass bottles in turn reduces the use of new glass and lowers the CO2 footprint.

This is why the Lavasonic HI series is enviro-classified

- Lower thermal energy consumption through the use of insulation, heat recovery, frequency-controlled pumps and grid or lightweight beams

- Economical fresh water consumption through optimised media flow, pressure regulation and energy concept

Benefits to you

Tailored to your needs

The ultrasonic modules in the pre-treatment system and the jetting pressure in the High Intensity module of caustic treatment system can be adjusted at any time. This enables the cleaning of a batch of empties to be tailored to needs without using excessive resources.

Consumption of resources

The new technology makes the goal of reducing resource consumption a reality. Reduce your heat demand by up to 30 % for one of the most energy-intensive machines in the filling line. In addition, you can reduce your fresh water consumption by up to 20 %, as well as your use of chemicals and feed of bulk glass. Furthermore, your CO2 footprint will be reduced by up to 35 %.

Digitally up to date

The latest technology used on the touch-screen and in the PLC ideally equips our machines for the new age of digitalization. For this purpose, we offer a wide portfolio of digital products for the line and machine, as well as individual setting options directly on the touch-screen.

Operation made easy

All double-end bottle washers offer easy access to important components so that cleaning and maintenance can be performed as quickly as possible.