Reliable filling of beer and flavoured beer in glass bottles

Mechanical filling system

- Reliable fill level determination via the vent tube

- End of filling after liquid contact with vent tube

- Low-oxygen filling through several pre-evacuation steps with intermediary CO2 flushing

- Electropneumatic filling valve

- One filling speed

Field of applications

- Suitable for all beer types

Output

- Up to 78,000 containers per hour

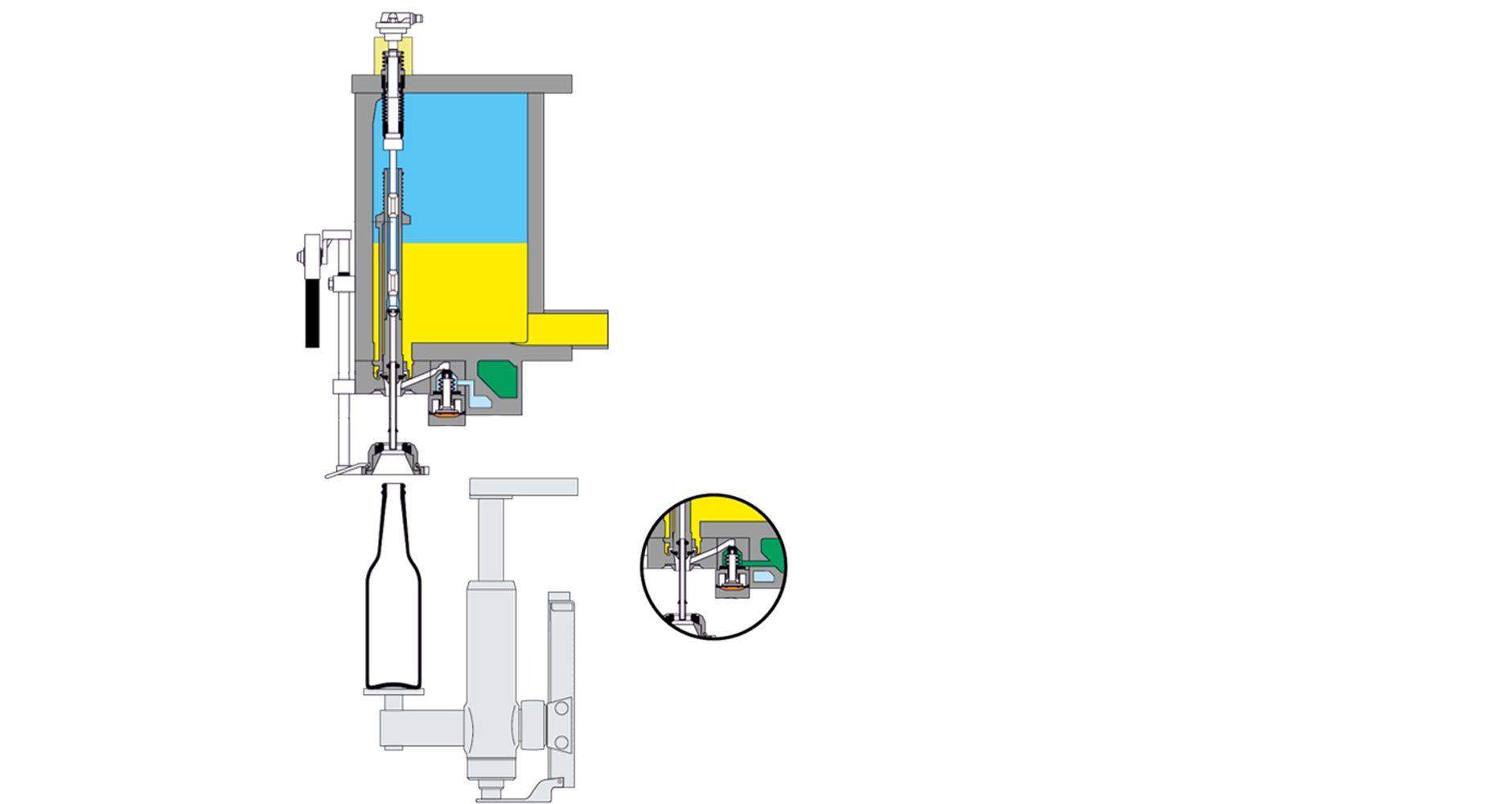

HRS = Height fillingsystem, Return gas tube, Short tube

Functional principle of the valve

First the glass bottle is pressed on and then it is pre-evacuated several times. The filling process will start as soon as the same pressure prevails in the ring bowl and the bottle. If the liquid level reaches the end of the vent tube, no more gas can escape from the bottle -and the filling valve closes. After a settling phase, the pressure in the head space of the bottle is released via the snifting valve and the filled product exits the machine.

Viscosity: < 10 mPa·s

Pulp: ≤ 0.4 mm/proportional < 10 %

Fibres: 1 x 5 mm/proportional < 5 %

Vacuum

Snifting/CIP

Vent tube

Product stem

Gas needle

Vacuum

Snifting

Gas needle - Product stem

Benefits to You

Best technological values

- Several pre-evacuations

- Optimal interconnected CO2 flushing

Hygienic design

- Self-draining surfaces

- Clean pneumatic components hosing and electrical wiring

Precision and long service life

- Use of special pneumatic components with a significantly higher life cycle than the one of conventional switching valves

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events