High-end variant for filling clear spirits and liqueurs in glass bottles

The more valuable the product the greater the loss caused by inaccurate filling. And Krones knows how to prevent this: Since the Modulfill HVT* is a specialist in maintaining precisely specified filling levels. For this reason, it is ideally suited for the precise filling of spirits.

At a glance

- Suitable for filling clear spirits and liqueurs into glass containers

- For outputs of up to 60,000 containers per hour

- Guarantees highest product safety thanks to well-thought-out process steps at the filler

- Guarantees optimum values in terms of standard deviation and alcohol losses

- Contains protection against explosion with state-of-the-art technology

- Can be combined with Krones rinsers

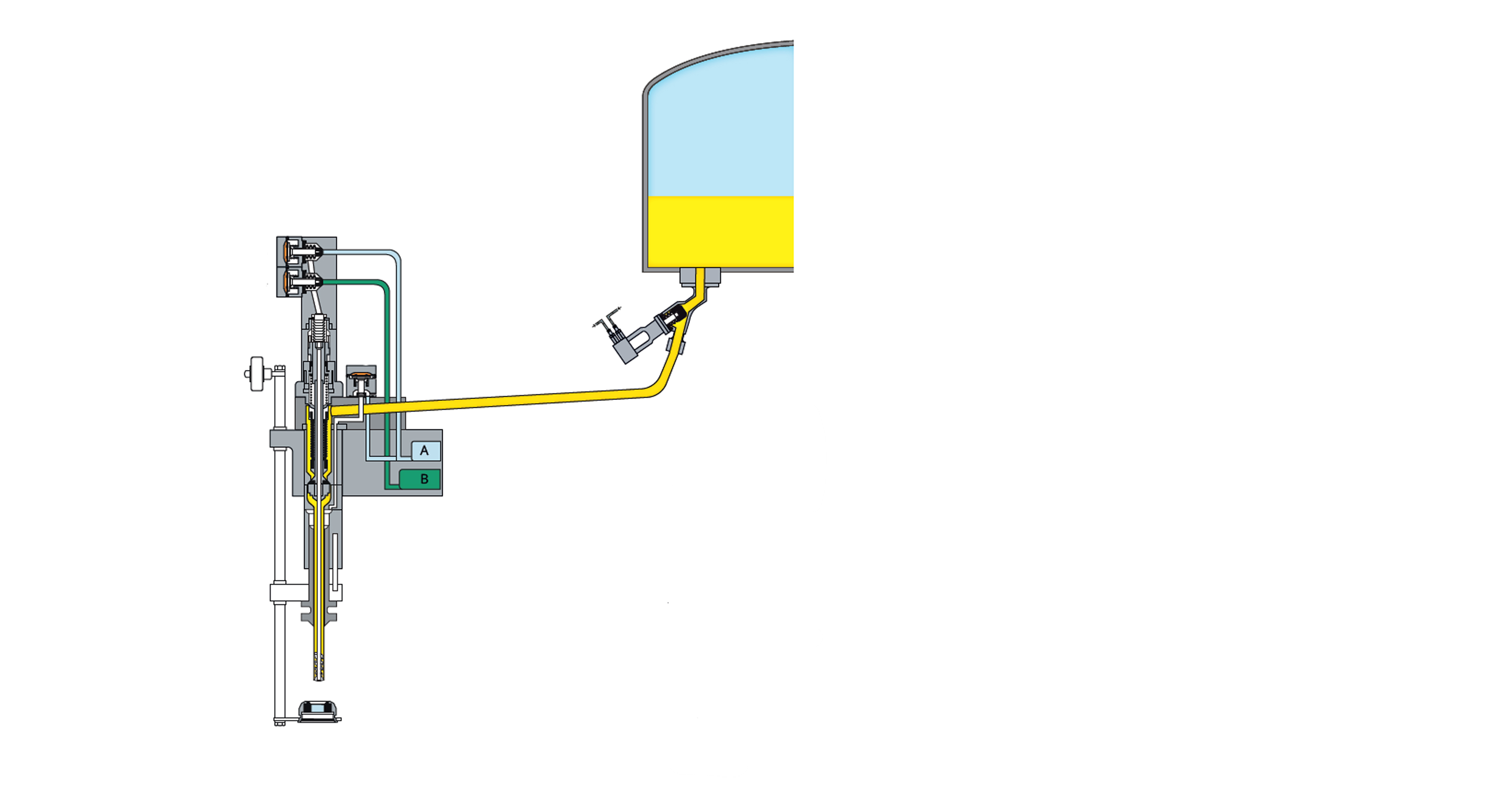

Functional principle of the valve

The Modulfill HVT is an electropneumatic filling systemwhich operates with a correction tube. The bottle is pressed onto the filling valve. Then the valve opens and filling begins. Once the liquid level reaches the end of the vent tube, no more gas can escape from the bottle. The filling valve is closed and electropneumatic vacuum correction starts. The correction quantity is drained into a separate channel.

Benefits to you

Practically no loss of alcohol (intensity)

-

Vacuum filling technology with separate vacuum channel

Highest product purity

-

No return of the product to the ring bowl during the correction phase

Almost no product loss

-

Return of the product via insertable troughs to a rework tank

Maximum filling accuracy

- Vacuum correction

- Low standard deviation of the fill level

- No product loss

High operator friendliness

- Automatic adjustment to new bottle heights

- Highest flexibility for change-overs

- Automatic vent pipe adjustment

Observance of safety regulations

- Requirements for protection against explosions are met

Variable filling speeds

- The speed is increased through overpressure filling

- Two filling speeds