The uncertain gas supply situation in 2022 set another energy building block in motion at Bergquell Brauerei Löbau in eastern Germany and subsequently triggered bold conversions. The company had long been a model company in terms of energy efficiency and was up to date with the technical possibilities. When the risk of a possible gas shortage with the threat of a supply stop for the brewery was difficult to assess, the owner took action without further ado: Steffen Dittmar brought Steinecker's energy consulting team into his company. With a great deal of creativity and commitment from both sides, the company became independent of gas as the sole basis for heat generation within just a few months and not only reduced its heat consumption once again, but above all also the heat flow peaks to record-breaking low figures.

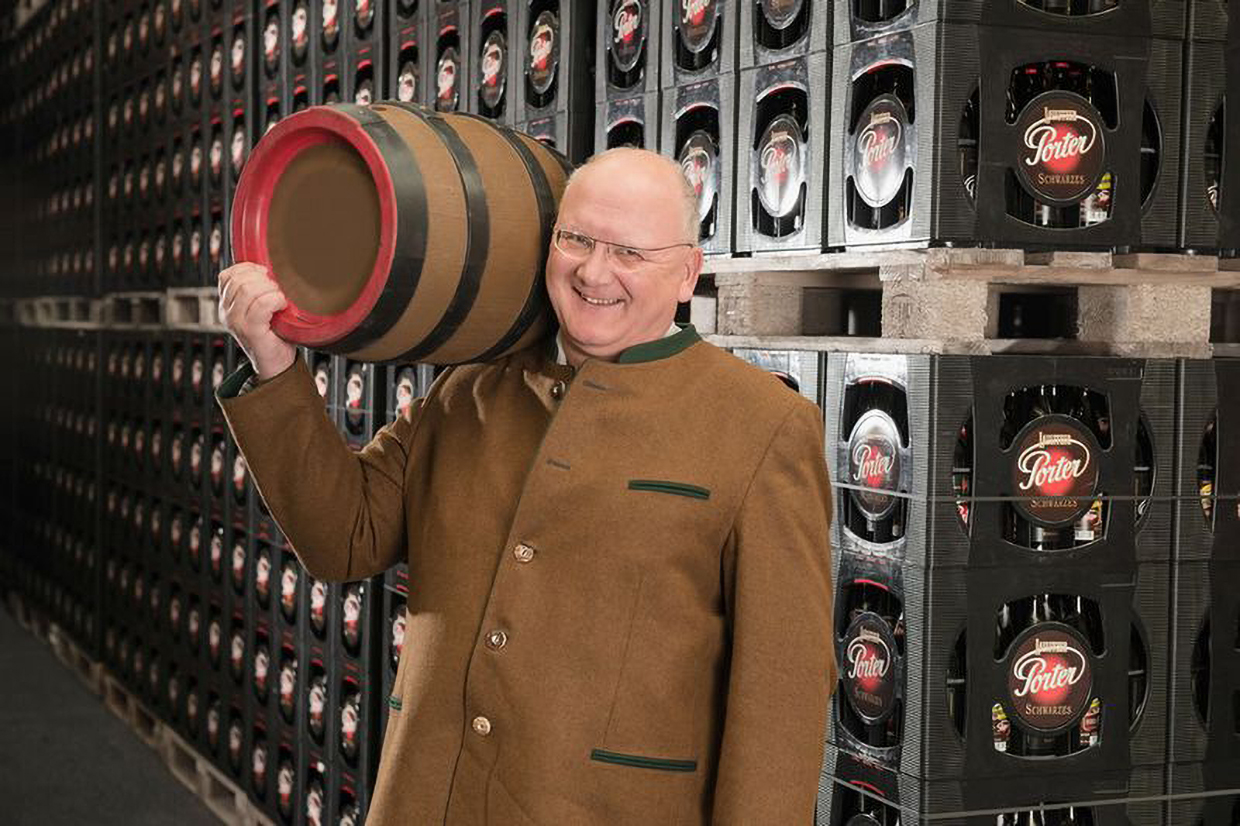

It was by no means surprising that the brewery chose this path, as tradition and state-of-the-art technology go hand in hand at Bergquell Brauerei Löbau. Founded in 1846 and run as a regional brewery with a low output until the mid-1990s, the company from Saxony has since transformed itself into a speciality brewery that delivers throughout Germany. In addition to classic beers such as Bergquell Pilsener and Helles, Bergquell is known above all for its innovative beer creations, such as the Lusatian Porter and the Cherry and Strawberry Porter. They are brewed using regional ingredients and traditional methods. At home in Upper Lusatia, the company's own horse-drawn carriage delivers beer barrels and at festivals, beer is served from specially converted Trabants in the company livery.