“Wow, great idea, great technology! But how can we earn money from it?” That is a question Dr Ralph Schneid from Steinecker has heard over and over again because translating his team’s innovativity into tangible benefits is part of his job. The basic rule here is: the more innovative the product, the greater the need for communication. That is vividly demonstrated by his development team’s latest coup, the Phoenix BMC. This is the punchy name of a biomass conversion system which opens up an additional line of business for breweries, as Dr Schneid explains: “The system extracts top-quality protein hydrolysate from organic brewing residues. As a result, by-products of the brewing process, which have so far been made little or no use of, can now be treated and turned into a valuable raw material for other industrial applications.”

The Phoenix BMC has met with a positive response at many different trade fairs and conferences. “There’s already a pronounced awareness for resource-efficiency in the brewing sector,” says Ralph Schneid. “So our customers were very receptive when we explained our idea to them.” But upcycling alone isn’t enough. It only makes sense to invest in a Phoenix BMC system if you’ve also got buyers for the end-product. And that is exactly where many breweries are still having difficulties because the market for protein hydrolysate is outside their traditional sales channels and must first of all be identified and tapped into.

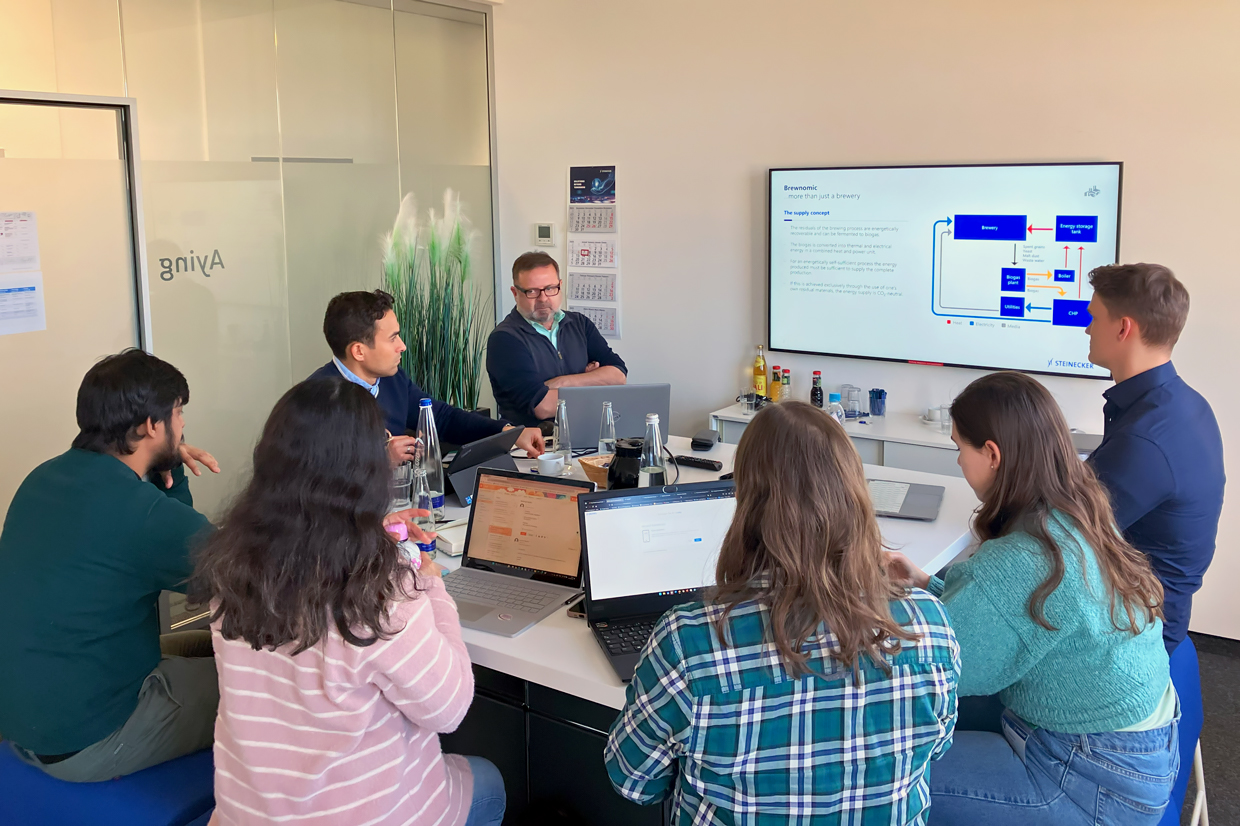

To lower this hurdle for its customers, Steinecker participated in the “1,000+” initiative launched by the Technical University of Munich, which brings together students and companies in order to devise and develop new approaches and solutions. The rules are clear: The company describes an actual problem encountered on the shop floor and sets the goals for a week-long project. A talented crew of up to five students then takes part in this project week, developing specific solutions to the problem at hand together with selected experts from the company.

The students didn’t just meet our expectations, they far exceeded them. It was a great experience for us to support this exceptional team. Dr. Ralph SchneidHead of R&D at Steinecker