Sound reasons in favour of the Contipure AseptBloc

The group opted for the Contipure AseptBloc for a number of reasons. One of crucial importance was without a doubt flexibility, which is a top priority for a co-packer like Hon Chuan. The block scores highly in terms of short cleaning and sterilisation times after every format change-over. Yet another plus can be found in the filler itself. Since it features the latest generation of PFR valves, the filling velocities can be individually matched to each product’s specific characteristics, thus ensuring efficient operation, particularly with a view to the frequent change-overs planned by Hon Chuan. As every beverage has its dedicated filling programme, the requisite adjustments at the filler can be made at the touch of a button, thus effectively preventing problems like fobbing during filling. That makes for minimised product losses while also further upgrading hygiene levels in the filling zone even for batches that run for a relatively long time.

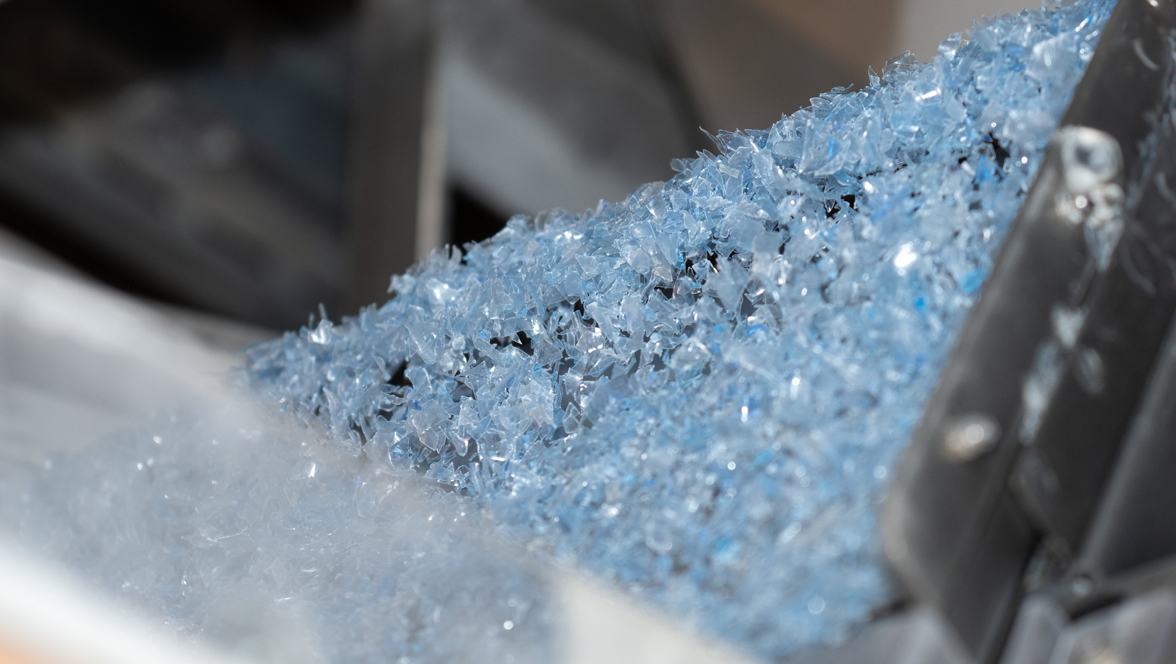

The Krones block system delivers excellent energy-economy and media-efficiency. The Contipure AseptBloc includes the latest generation of the Contiform stretch blow-moulder, which features an improved infrared heating module that reduces the energy needed for heating the preforms by another five per cent as compared to the predecessor module. Furthermore, the integrated Air Wizard technology enables compressed-air consumption to be cut by over a third, depending on the type of container produced.