In Dar es Salaam, Tanzania’s bustling metropolis on the Indian Ocean, thirst is literally in the air. Tropical temperatures and high humidity make clean drinking water not only a basic need but a vital necessity. One product that is quenching that thirst is Afya – one of the country’s most popular bottled water brands. The name means “health” in Swahili, which is appropriate since that is precisely what the Afya brand stands for.

Watercom is setting new standards – in water and beyond. The company has demonstrated its innovative spirit by commissioning a state-of-the-art line for producing and filling PET bottles. At its heart is a Contiform Bloc BF from Krones – a compact, high-speed solution.

The company behind the brand is Watercom, Tanzania’s second-largest beverage producer. Established in 2012, Watercom is headquartered in Dar es Salaam, the economic and cultural heart of Tanzania. The company is growing, and with it the need for powerful filling technology. The source of its success lies deep below the Earth’s surface – an underground stream that runs below the Kigamboni district in the southern part of Dar es Salaam. It is from this natural reservoir that Watercom draws the water for Afya. And they fill it on state-of-the-art machinery from Krones. It all began in early 2021, when the first line was put into operation. Two more lines soon followed, in mid-2023. “Partnering with Krones has been transformational”, says Nitin Kale, Operations Manager at Watercom. “Their technology brought precision, reliability, and world-class efficiency to our operations – enabling us to meet growing demand while maintaining the highest quality standards. It’s not just about machines; it’s about a partnership built on trust, expertise, and shared vision.”

New line for soft drinks

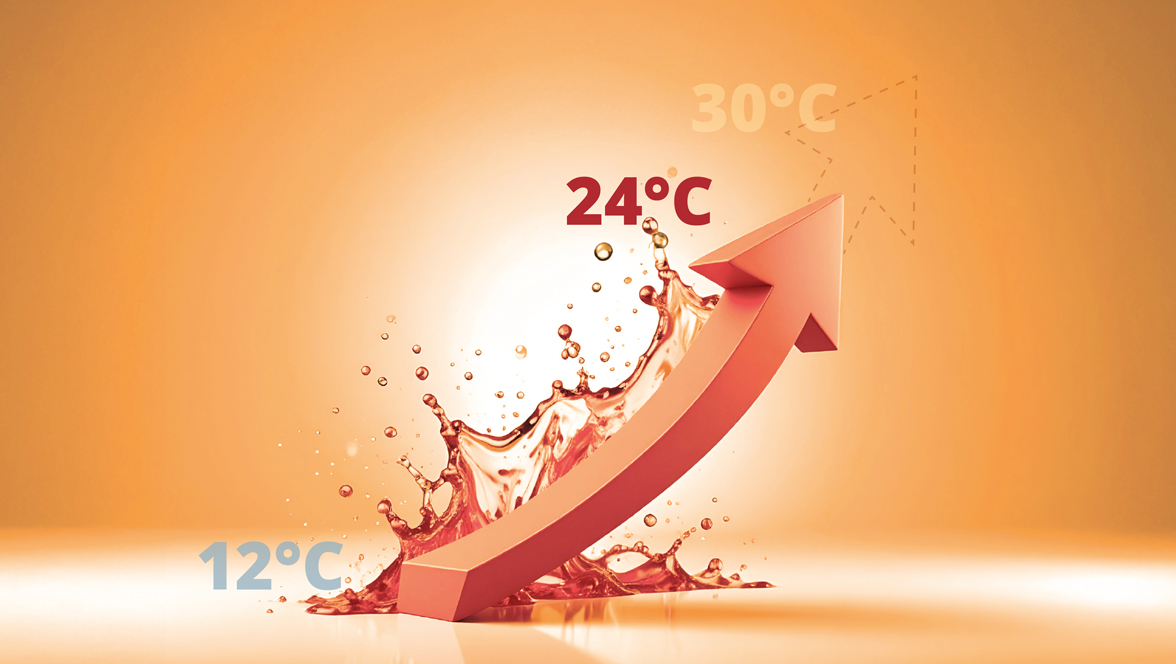

But Watercom’s portfolio is not limited to water alone. Energy drinks and carbonated soft drinks (CSDs) are also part of the mix. The company upgraded its equipment for handling this product line in early 2025, adding a brand-new high-speed PET line from Krones, which was installed in early January and commissioned at the end of April.

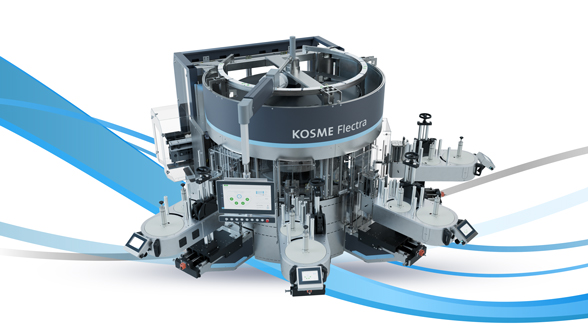

At its heart is a Contiform Bloc BF – a compact block solution that unites the stretch blow molder, filler and capper. The block makes it possible to run a highly efficient operation on a tiny footprint and is ideally suited for high-speed production lines like the one at Watercom.

High speeds to meet high demand

This fourth line has been running at record speeds since early May, filling 82,500 bottles per hour (all of which hold 300 milliliters). With that, the line is the fastest CSD filling line not only in Tanzania but in all of Africa. Speed was the deciding factor for Watercom because demand for the company’s products is growing – and Watercom intends to meet it without compromising on quality. “Our commitment is to the highest standards and never compromising on quality and food safety – with a major milestone in our food safety achieving the FSSC22000 certification late last year”, says Bernard Msemembo, SHEQ* Manager at Watercom. “This globally recognized certification reinforces our commitment to continue improvement and compliance with the highest food safety standards.“

* SHEQ: Safety, Health, Environment, Quality

About the project

Customer: Watercom Tanzania Limited

Project: High-speed PET line for CSDs

Location: Dar es Salaam, Tanzania

Scope: