More output achieved in the same space

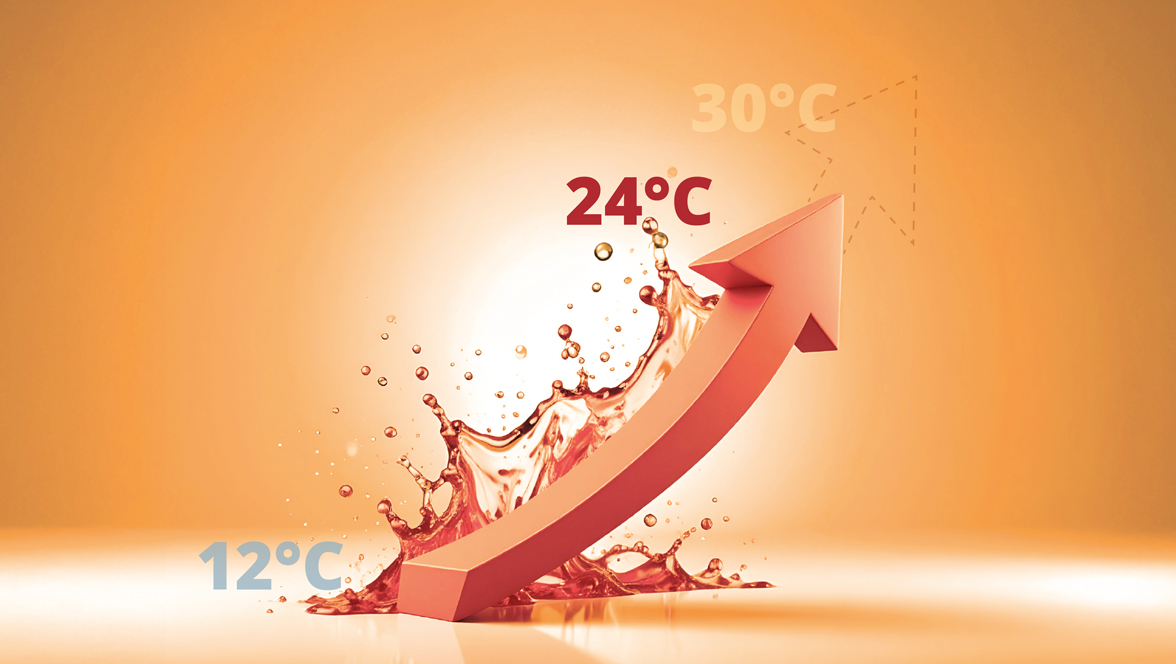

SML CI is again relying on Krones block technology for its third PET line. However, this time the decision-makers did not go for another blow-moulder/filler block but instead for an ErgoBloc L, their first wet-end block. Rated at 55,000 containers per hour, it significantly exceeds the outputs of the existing lines and has a small footprint into the bargain. Its space-saving design integrates the processes of stretch blow-moulding, labelling, filling and capping in a single block. That is a real game-changer for SML CI since it provides massive increases in production volume while simultaneously minimising space requirements. “Due to our fast-growing business, we were facing space constraints that limited our ability to install additional capacity“, explains Nader Sayegh. “The ErgoBloc was the ideal solution to avoid major civil engineering investments. In addition, the line speed was increased from 35,000 to 55,000 bottles per hour on a single stock keeping unit – a crucial step to ensure maximum productivity in an increasingly competitive market.”

SML CI is signposting the way not only in terms of technology but for its geographical region, too, since its ErgoBloc L is the first of its kind in all of Northwest and Western Africa. Moreover, the new line has been purpose-built for digital solutions, thus making any future production optimisation a whole lot easier and providing SML CI with the best possible footing for further growth. It is scheduled to go into operation in early 2026 and expected to help the company take the next step on the ladder of success. The collaboration with the Krones Group will also continue into the future: SML CI recently ordered a PET line for edible oil from Kosme.