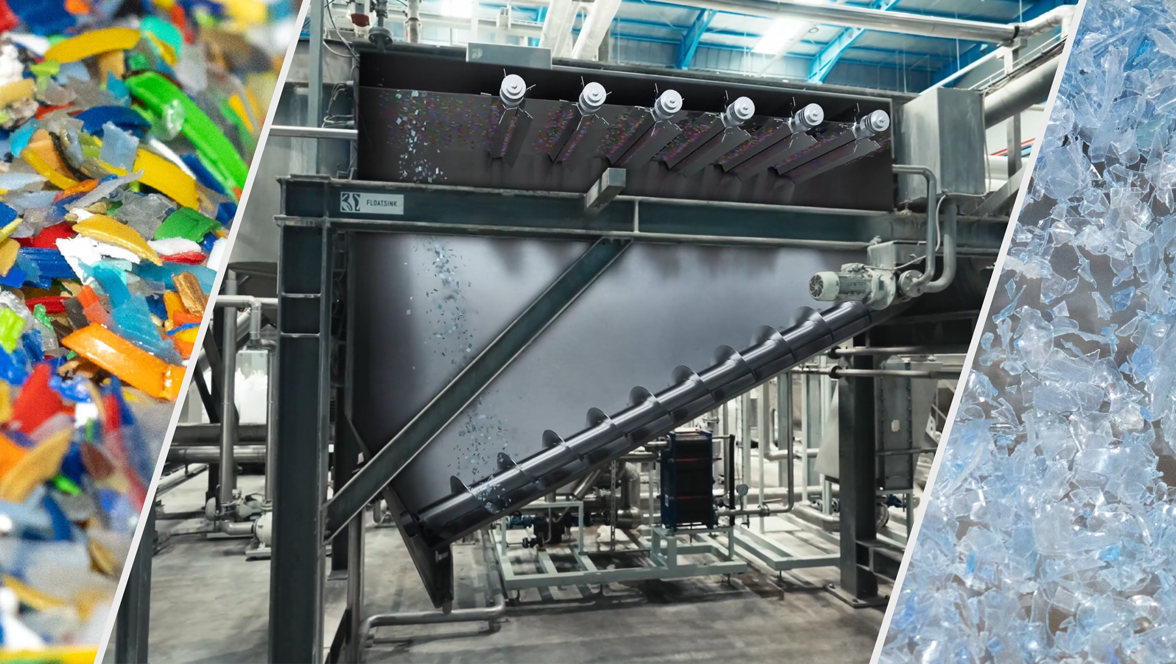

As you will know, the use of recycled plastics offers many advantages: It reduces the amounts of CO₂ emitted during production of plastic packaging and the dependence on fossil resources, and it helps combat global littering. The bad news is that there’s still plenty to do because according to Plastics Europe only just under 27 per cent of all plastic waste in Europe is at present recycled. The percentage for recycling on a global scale is even smaller. The good news is that numbers are rising, thanks not least to countless regulations introduced by governments all over the world. A variety of legal requirements have been (or are currently being) approved in the EU, such as:

- The Plastic Tax enacted in 2021: That is a levy to be paid by companies on non-recycled plastic packaging to the amount of 0.80 euros per kilogram. The scheduled year of introduction in Germany is 2025.

- Mandatory use of recycled material for plastic packaging: PET beverage bottles, for example, must be made of at least 25 per cent rPET as from 2025, and of at least 30 per cent rPET as from 2030.

- A mandatory deposit system for PET beverage bottles and beverage cans is scheduled to be introduced in each EU country as part of the Packaging and Packaging Waste Regulation (PPWR) as from 2029.

- Tethered caps make sure that a higher number of caps are kept in the cycle of re-usable materials when non-returnable beverage bottles are recycled.

And worldwide:

- In the past few years, India, Thailand and South Korea have approved recycled plastics for food contact and formulated some ambitious goals. India, for example, has specified a proportion of 10 per cent recycled materials in rigid plastic packaging as from 2025 .

- In the USA, some states like California are leading the way with deposit systems and binding rPET quotas.

- The UN’s Intergovernmental Negotiating Committee on Plastics Pollution has been tasked with developing an instrument by the end of 2024, which is to be legally binding on an international scale and aimed at reducing plastic littering worldwide.