Recognised early on: The future of sustainability

Krones starts the enviro sustainability programme in order to systematically improve the energy and media efficiency of its product portfolio. The resulting solutions range from systems for heat recovery to an energy self-sufficient brewery.

Krones machines become more economical

The enviro programme systematically steers the entire product development process towards sustainability and is based on a management system certified by TÜV SÜD (technical inspection authority).

The result is machines that enable energy- and media-efficient production and can also provide transparent proof of this.

Efficient water treatment system

The Hydronomic water treatment system delivers optimum water quality for beverage producers. The system works with reverse osmosis technology, consumes comparatively little energy and uses rinsing water and cleaning chemicals sparingly.

Innovative block concept

With the ErgoBloc L, PET containers can be produced, labelled and filled - all on a single compact system. Thanks to its high output and low operating effort, the wet part block quickly becomes a bestseller.

Heat recovery during brewing

Sustainable development for the brewing process: The EquiTherm energy recovery extracts energy from the wort after boiling so that it can then be reused in the mashing process. The first user of EquiTherm, Bergquell Brauerei Löbau, saves more than 30 percent of primary energy.

Software for process control

Krones summarises all its IT products under the SitePilot umbrella brand. The software solutions enable the processes of a filling and packaging line to be controlled, transparently tracked and documented. The individual modules inform management and employees about all processes in production.

Completely sterile production of plastic containers

The Contiform AseptBloc sterilises the preforms of plastic containers with gaseous hydrogen peroxide. Afterwards, the preforms are then blown into bottles under sterile conditions. A sterile process chain is created in the entire machine block, from stretch blow moulding to filling and capping the products.

Resource-saving filling of sensible beverages

To enable hygienic production in sterile atmosphere, the Contiform AseptBloc is completely encased. As the preforms are already sterilised before becoming bottles, the line requires less time, energy and sterilising medium. The beverage is filled in the integrated filler without risk of contamination from microorganisms.

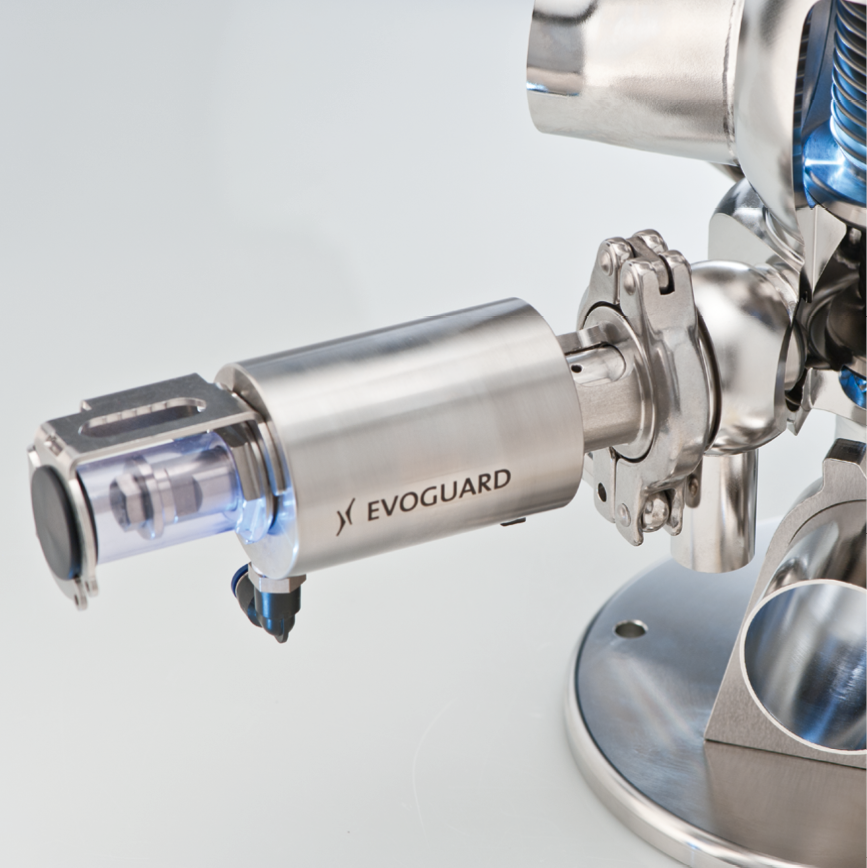

Subsidiary for valves and pumps

Evoguard GmbH develops and markets its own valve and pump series and quickly becomes successful. The wholly owned subsidiary of Krones moves into a newly built production building in Nittenau, which is expanded several times in the following years.

New CEO Christoph Klenk

After around 20 years as CEO, Volker Kronseder reaches retirement age and steps down from the Executive Board. Christoph Klenk, who had previously been responsible for Finance, Controlling and Information Management on the Executive Board, is appointed as his successor. The 2016 Annual General Meeting elects Volker Kronseder as the new Chairman of the Supervisory Board.

Expanded intralogistics portfolio

Krones acquires a majority stake in the Italian intralogistics and material flow expert System Logistics S.p.A. The Krones Group's portfolio now also includes fully automated high-bay warehouses with driverless transport systems. This covers the entire value chain in the food and beverage industry and expands the "one-stop shop" concept.

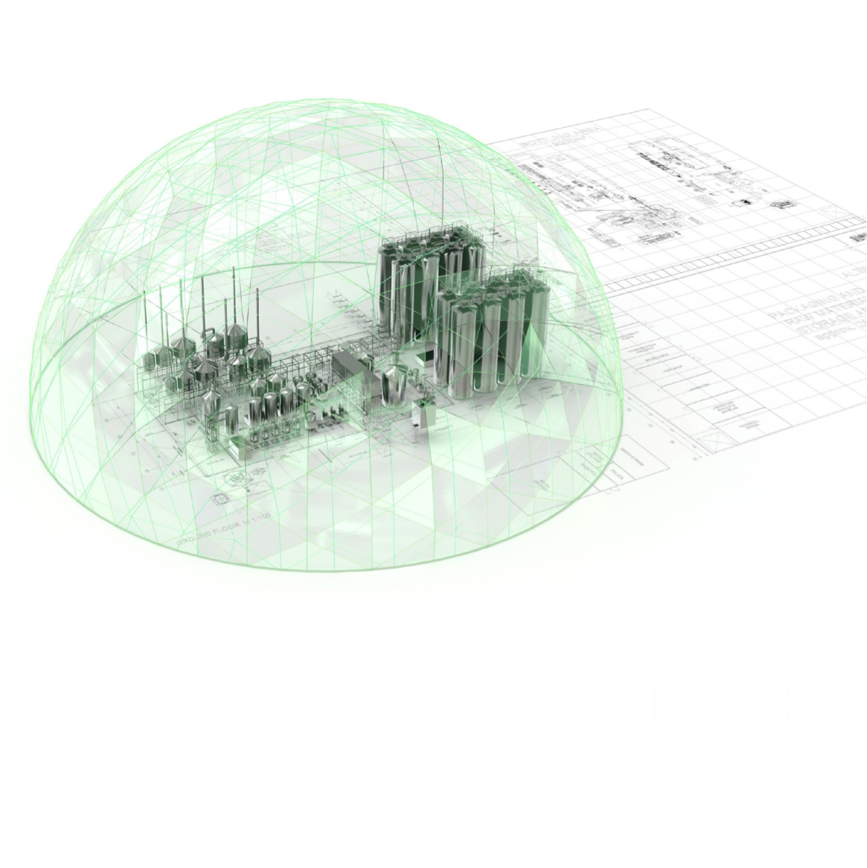

The brewing power station

Krones presents the concept of a brewery that can operate self-sufficiently in terms of energy. The overall Brewnomic solution consists of several components that make it possible to reduce energy requirements, recover heat, use renewable energies and utilise the residual materials from the brewing process for material and energy recovery.