Early growth: International locations and new machine types

The establishment of the first subsidiaries abroad takes the export of machines to a new level. To better fulfil the requirements of the customers, Krones includes empty bottle inspectors, bottle washers and fillers into the portfolio.

First foreign subsidiaries

Krones' own agencies in the USA and France are the first step towards serving international markets. Discussions in the local language, fast customer contact - beverage producers in the USA and French winegrowers are soon convinced of the quality of the machines. A further subsidiary in Great Britain is established in 1975.

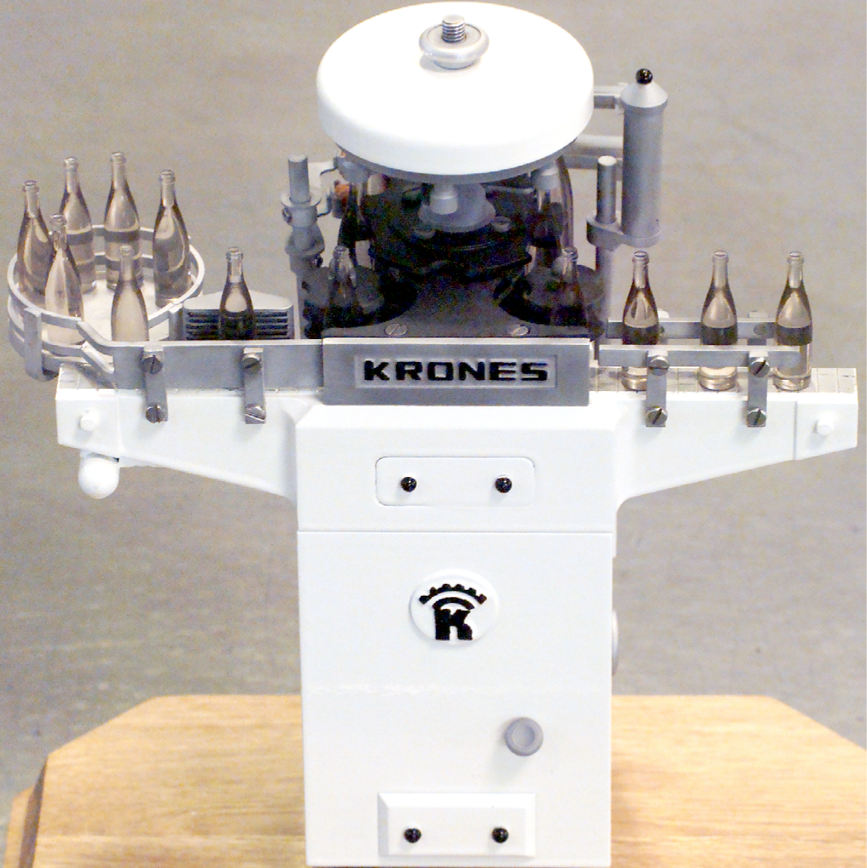

In the spirit of the times: The new logo

Krones presents itself with a new representation of the company name made up of angular, elongated letters. The lettering was initially often combined with the existing "K" logo. In the 1970s, it became a contemporary company logo with outlined letters.

Milestone for fast labelling

The high-performance labelling station with oscillating glue pallets is a ground-breaking innovation on the market. A fixed label magazine and the oscillating movement of the aluminium pallets for label removal enable outputs of 36,000 bottles per hour. The label gripper on a rotating cylinder removes the label from the pallet and transfers it to the bottle.

Automatic empty bottle inspection

The first empty bottle inspector automates the visual inspection of empty bottles in beverage production facilities. The machine uses an optical-electronic device to detect foreign objects and contamination inside the bottles. Contaminated bottles are automatically discharged onto a collection table.

New in the product range: Bottle washers

Krones adds bottle washers for returnable bottles to its portfolio. Contistella and Contiranta - these are the names of the bottle washers from Krones' scope of supply. The single-end and single-tank machines are available with an output of between 5,000 and 30,000 bottles per hour.

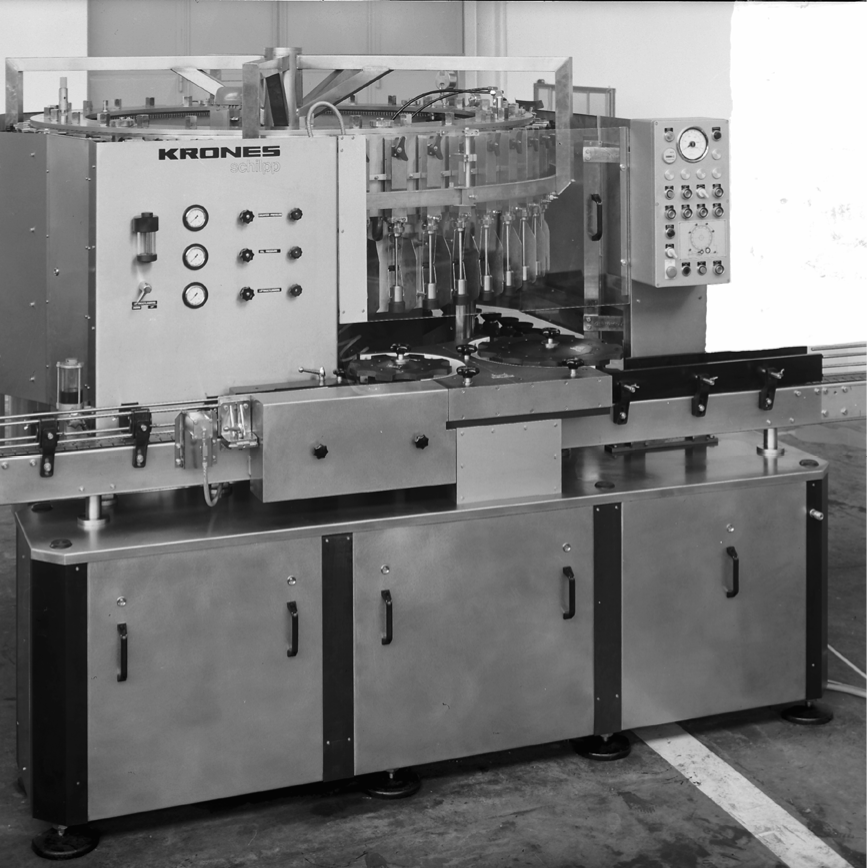

First step towards a complete line: Fillers

Another new addition to the range is a filling system with a centralised container, which was initially designed with a partner. Previously, the labellers were often only an addition to a line from another supplier, but now Krones can offer the complete wet section with its own filler.

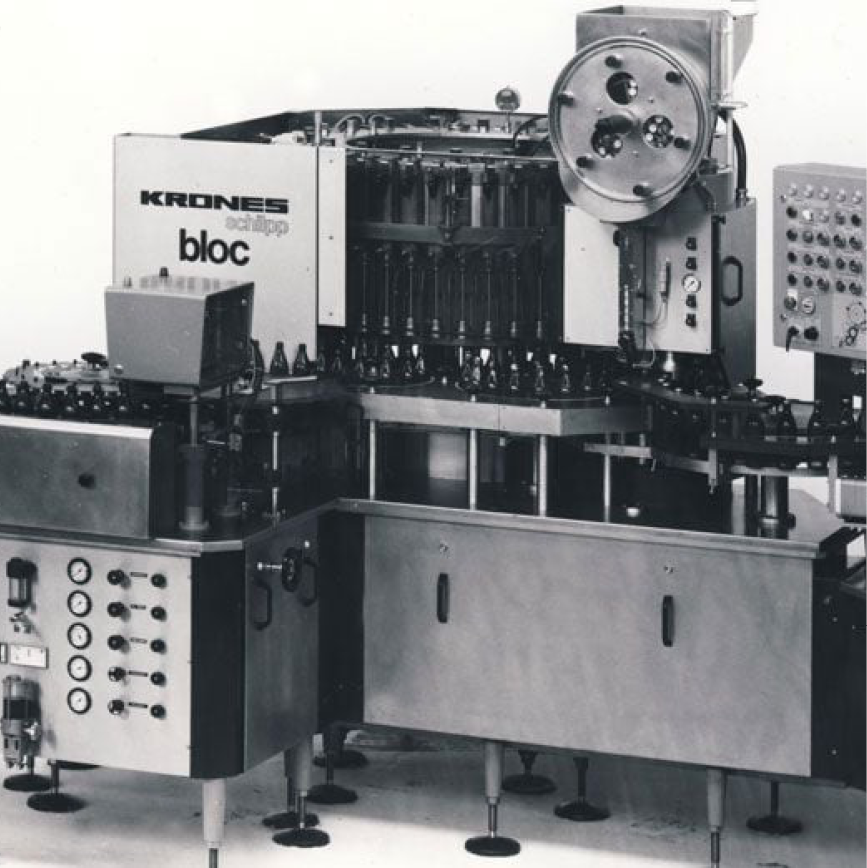

First of its kind in the world from Neutraubling: The "Krones Bloc"

The "Krones Bloc" is constructed with a filler, capper and labeller without any intermediate conveyors which is a completely new machine arrangement at the time. The idea was based on the simplified operation by just one person and the reduced space requirement. Today, these block systems have long become the standard.