Digital solutions for the industry of tomorrow

With the use of artificial intelligence and the development of cloud services, Krones is driving digitalization in the beverage industry and at the same time opening up new, promising business areas.

Entry into injection moulding technology

With the acquisition of MHT Mold & Hotrunner Technology AG, Krones expands its expertise in the field of PET bottle production. The company specialises in high-precision mould modules for injection moulding machines. These systems produce the preforms that are later blown into PET bottles by machines such as the Krones Contiform.

New plant in Hungary goes into operation

At the Debrecen site, Krones opens a state-of-the-art production facility covering 150,000 square metres and employing 500 people. They manufacture machine components - such as bottle cells or drip trays - and assemble conveyor belts for complete filling and packaging lines.

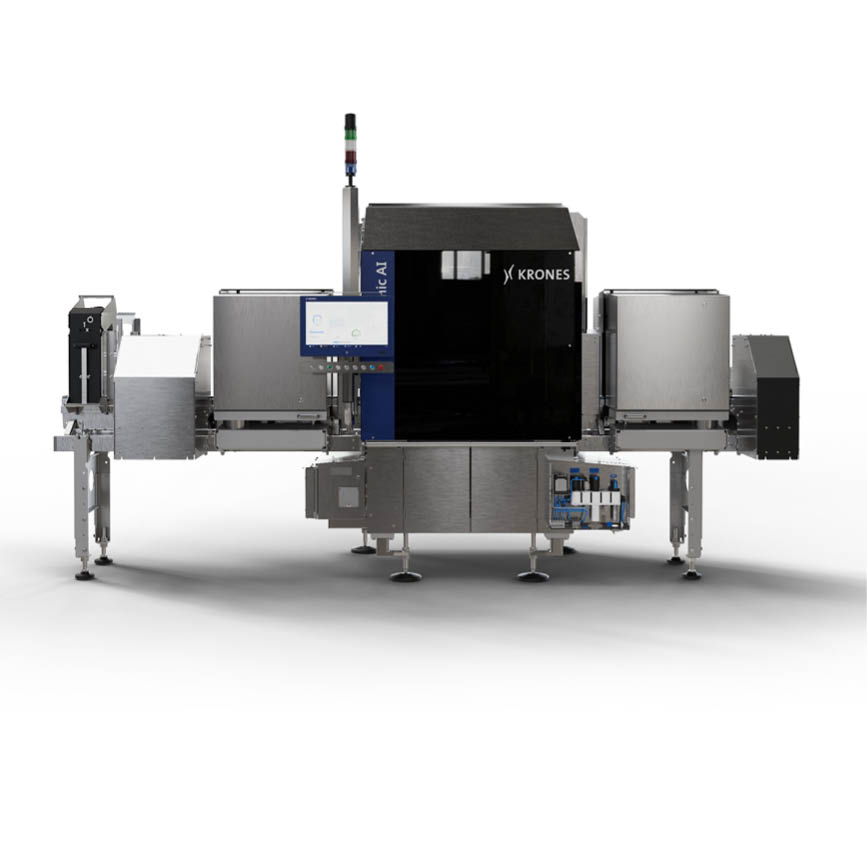

Deep learning for improved inspection results

The Linatronic AI empty bottle inspection machine is the first Krones machine to utilise artificial intelligence. With the help of neuronal networks, it achieves unrivalled accuracy when analysing bottles. Even drops of water are now recognised with a reliability of 99.9 percent.

The evolution of inspection technology

Harmless water droplets or real dirt? To detect this difference, the Deep-Learning system of the Linatronic AI is trained with thousand sample images. The result: A significantly lower bottle rejection rate than with conventional inspectors.

Digitalization moves to the centre of development

In the spirit of a system supplier, Krones is linking the areas of mechanical engineering and digitalization even more closely in the Krones Ecosystem. This spans all of the Group's new machines like an invisible dome. The collected line and production data forms the basis for utilising existing cloud services and, in future, other digital solutions from Krones.

New target vision "Solutions beyond tomorrow"

Krones is formulating a new vision and ambitious goals for the entire Group. The biggest driver of innovation in future will be sustainability, which is also becoming increasingly important to customers. Krones will be rigorously applying this sustainability claim to its entire portfolio in the area of process technology, filling and packaging technology, and intralogistics. Digitalization and fully comprehensive production services will play a decisive role for customers in order to both reduce resource consumption and increase performance.

Artificial intelligence in the stretch blow moulder

Ambient temperature or air humidity, preform weight or percentage of recyclate: If such framework parameters change, the stretch blow moulding process for the production of plastic bottles must always be readjusted or even reset. But instead of being performed manually by the operators, this job is now taken over by the Contiloop AI intelligent control system – precisely, quickly and fully automatically thanks to artificial intelligence.

New strategy for climate protection

Krones is expanding its existing climate strategy in order to systematically reduce its greenhouse gas emissions: According to the Executive Board's resolution, the entire Group is to achieve the Net Zero standard by 2040 in accordance with the scientifically recognised Science Based Targets initiative (SBTi). This envisages reducing 90 percent of the emissions generated in the value chain and neutralising the remaining ten percent. The basis is the year 2019.

Takeover of Netstal Maschinen AG

Krones acquires 100 percent of the shares in the Swiss company Netstal, a leading manufacturer of injection moulding machines for PET preforms and caps.

With this addition, the Krones Group now offers all the technologies required for closed PET loop solutions: Starting with injection moulding of preforms, through PET container production, filling and packaging, to the recycling of used bottles.

Reorganisation of the plastics recycling division

The construction of recycling systems for plastics, part of Krones AG's portfolio since 2002, will be bundled in the subsidiary Krones Recycling GmbH. Thanks to leaner processes and structures, the new company based in Flensburg can react quickly to changes in the recycling market and continue to develop in line with market requirements.