Developmental years with pioneering technical achievements

Hermann Kronseder founds a small production facility for labellers in Neutraubling near Regensburg. Within just a few years, he succeeded in using technical innovations to become one of the leading providers of bottle labelling machines.

Founding the company

Hermann Kronseder starts with the production of labellers. The self-built workshop with a floor area of around 100 square metres is the production site of the first semi-automatic labelling machines. A lathe, a boring mill, a drilling machine and a sanding block are all the tools that the master mechanical and electrical engineer Hermann Kronseder needs.

The first company logo

Right from the start of his business, Hermann Kronseder focussed on recognition: Soon after the company was founded in 1951, the company's first logo was created. It shows a stylised "K" for "Krones" and above it a crown made of a sprocket fragment.

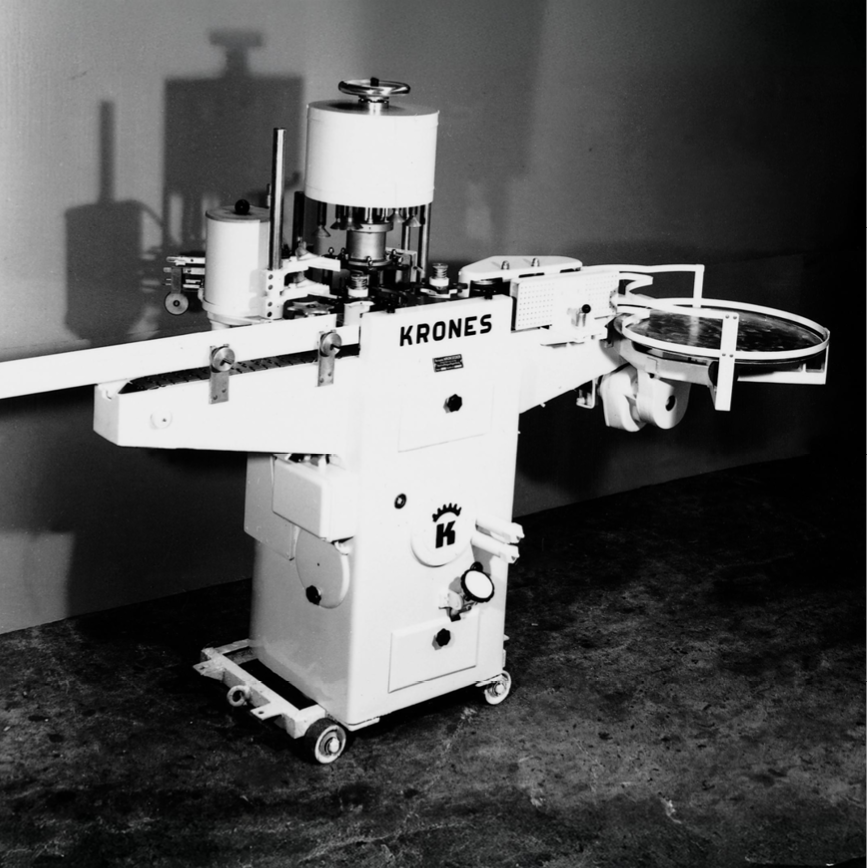

Success with semi-automatic labellers

A machine made from just 150 parts: The steel version of the St 1500 labels 1,500 bottles per hour on six bottle supports. The successor model Piccolo already processes 2,100 bottles per hours with its closed cast housing and bottle table made of light metal.

Full-automatic labelling for the first time

Krones is offering a novelty with the Super model: The fully automatic labelling of upright bottles enables outputs of up to 4,500 bottles per hour. The higher output is a result of the "upright position" and, for the first time, the bottles are labelled upright instead of lying. This puts an end to the tedious task of placing and removing bottles by hand.

The Super in action

This Super labeller version applies shoulder and swing-stopper labels to bottles. After pressing on the labels, the bottles are rejected to a discharge table.

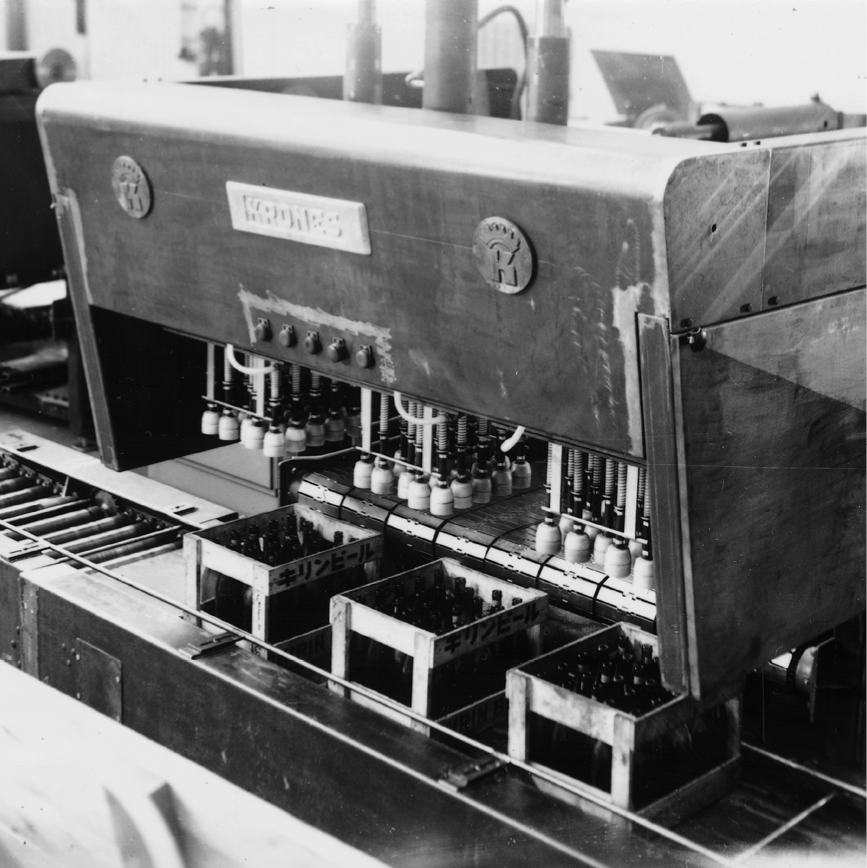

New on offer: Packer and unpacker

With the packer and unpacker, Krones presents clever solutions for other fields of the beverage industry - output of up to 1,800 crates per hour. The new packers are met with with keen interest from Japanese breweries. However, the business segment is discontinued in the mid-1960s in favour of the increased development of labellers.

Fully automatic packing of bottles

The filled bottles are divided into lanes on the feed table and fed to the packer. The gripper heads raise the bottles there and put them into automatically provided wooden crates.

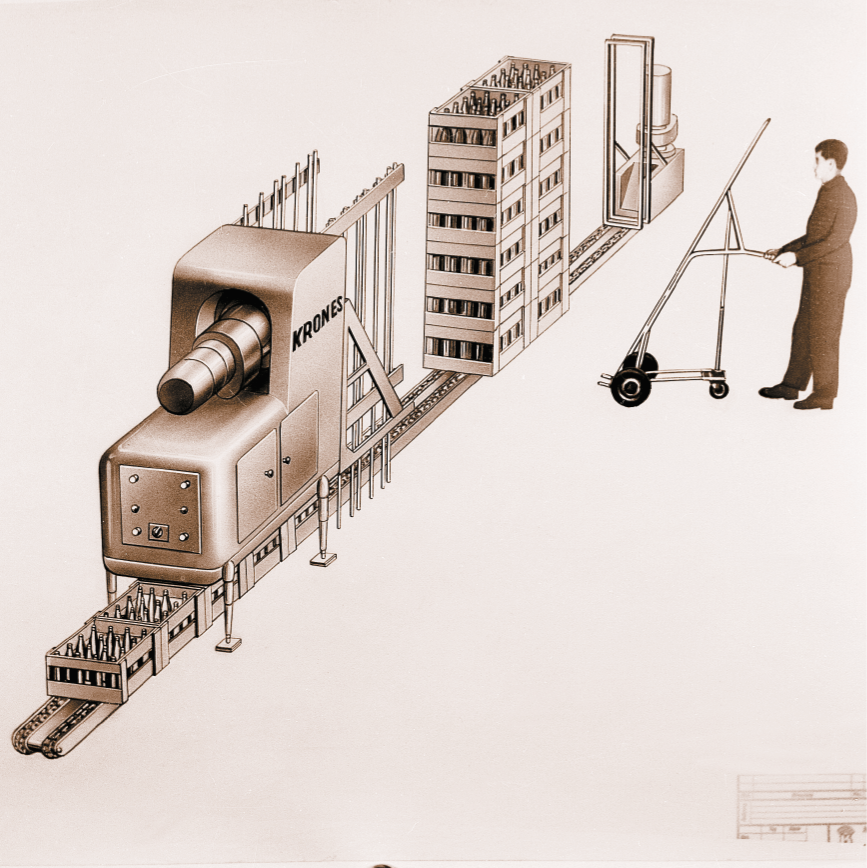

Stacking of crates more easily

Stacking swing stopper bottles weighing 800 grams in wooden carriers is the daily business for warehouse workers in the 1960s. Krones provides relief and higher outputs with the Stapelmax. 1,200 crates per hour can be moved easily and efficiently in the warehouse.

Motor instead of muscular strength

The crates are individually fed on a conveyor to the Stapelmax. The machine lifts the crate that arrives first and then sets it down on the next one. This process is repeated until the required stack height is reached.

The fastest labeller in the world

The labelling cylinder removes the label from the magazine using vacuum suction nozzles and guides it past the stationary glue roller. The bottle is labelled while being transported. At 50,000 bottles per hour, this is the fastest labeller in the world at the time.