Beverages in PET: Innovations for a global market

Keeping an eye on the cycle right from the start: Krones launches its first stretch blow moulder for the production of PET bottles and also works on a concept to recycle the used containers to a food-grade quality.

Machine for the production of PET bottles

Krones develops the compact, two-storey Contiform machine for heating preforms and stretch blow moulding PET bottles. This innovation also meets with a positive response from the major soft drinks bottlers. A successful start to the new technology - and to a completely new business field.

Expansion of packing and palletising technology

Krones acquires some areas of the insolvent Max Kettner GmbH, a manufacturer of packers and palletisers. This company had a good reputation in the industry, but had to give up after making strategic mistakes. Krones now consolidates the entire packer and palletiser production in Rosenheim.

Continuous beverage mixing

The product range is steadily expanded: Just in time for the Intervitis trade fair for fruit juice and wine producers, a compact beverage mixer and carbonating system is presented in the form of the MSF mixer.

IT and intralogistics

The flow of information is becoming increasingly important. New IT solutions for production data acquisition, process control systems and intralogistics concepts enable Krones to act as a full-service provider for process sequences in beverage companies.

One-way containers in growing trend

The new Variopac and Wrapapac packaging machines ensure safe secondary packaging on the way to the retailer. The machines for the film packaging of containers and for the packaging of containers in full wrap-around cartons are in line with the trend towards compact packs for non-returnable containers.

Mobile and communicative

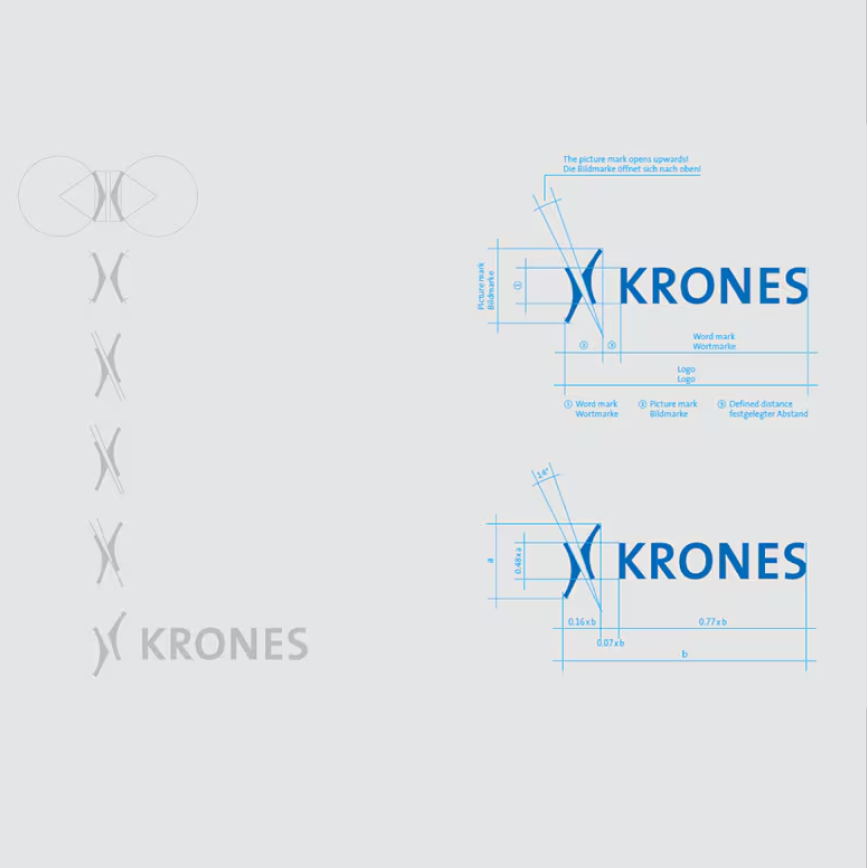

Modern logos for Krones AG and its subsidiaries and a new corporate design are introduced. The logo shows two stylised, slightly offset arrowheads, symbolising dynamism and determination. The company name follows in lean characters.

Bottle-to-bottle recycling

The utilisation of the raw material PET in the cycle becomes part of the corporate strategy. In order to make used PET available for reuse in bottle production, bottle-to-bottle recycling concepts are added to the portfolio. This produces food-grade PET for the production of new bottles.

Specialist for small outputs

By acquiring a stake in the Kosme Group, Krones offers medium-sized customers interesting entry-level models. The Austrian-Italian group manufactures fillers, labellers and packaging machines as well as straight-line stretch blow moulding machines for the low output range.

New service centre in China

The significant growth rates on the Chinese market prompt Krones to strengthen its presence in China. In order to provide comprehensive support to Chinese beverage producers, a local spare parts production facility and a training centre are set up at the Taicang site near Shanghai.