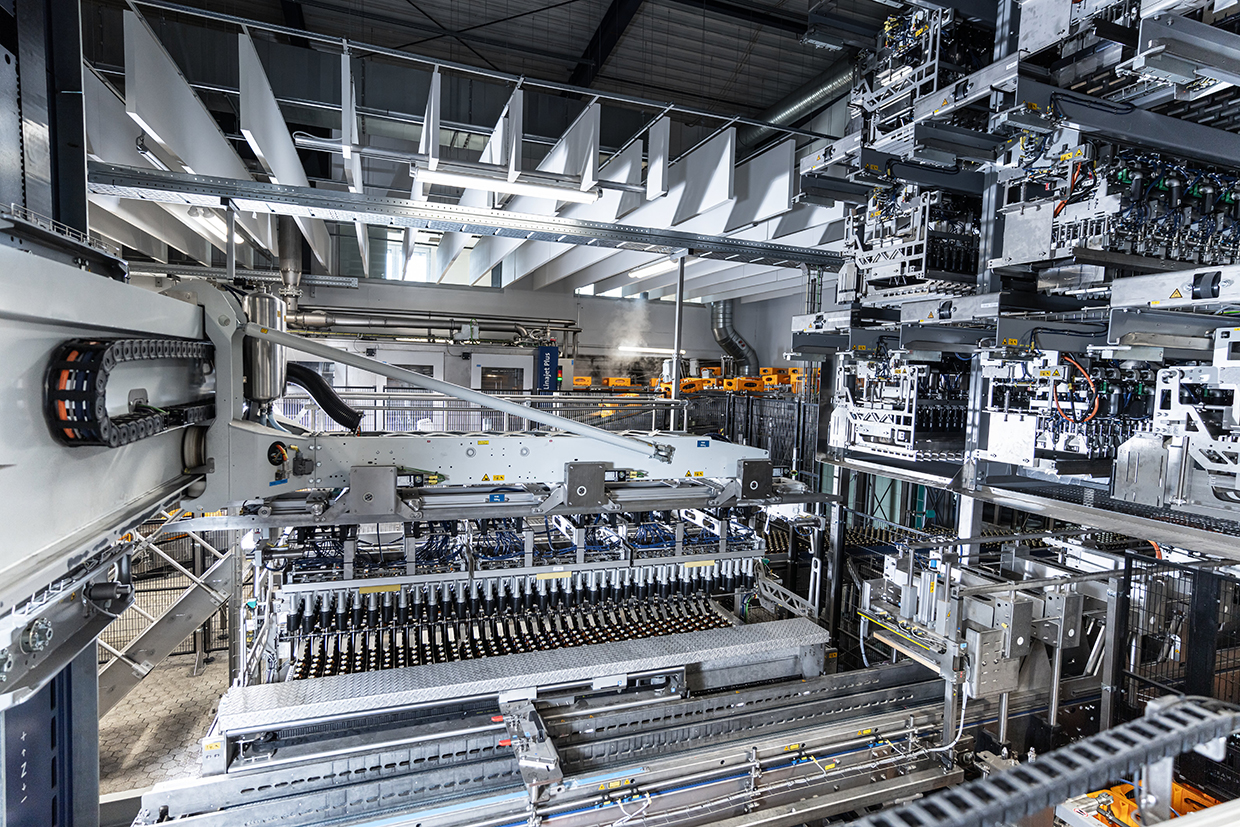

The new bottling line offers a huge spectrum of options. It can produce any of 70 different stock keeping units (that is, configurations of bottle and pack type and size), ranging from 0.2 litres right through to the classic half litre and from four- and six-packs to various crates. “The product diversity is downright incredible,” says Henning Vormbrock. And the new mixing system has now enabled Herforder Brauerei to produce non-alcoholic drinks like tonic water as well, a whole new chapter in the brewery’s success story.

Smarter, faster, more efficient

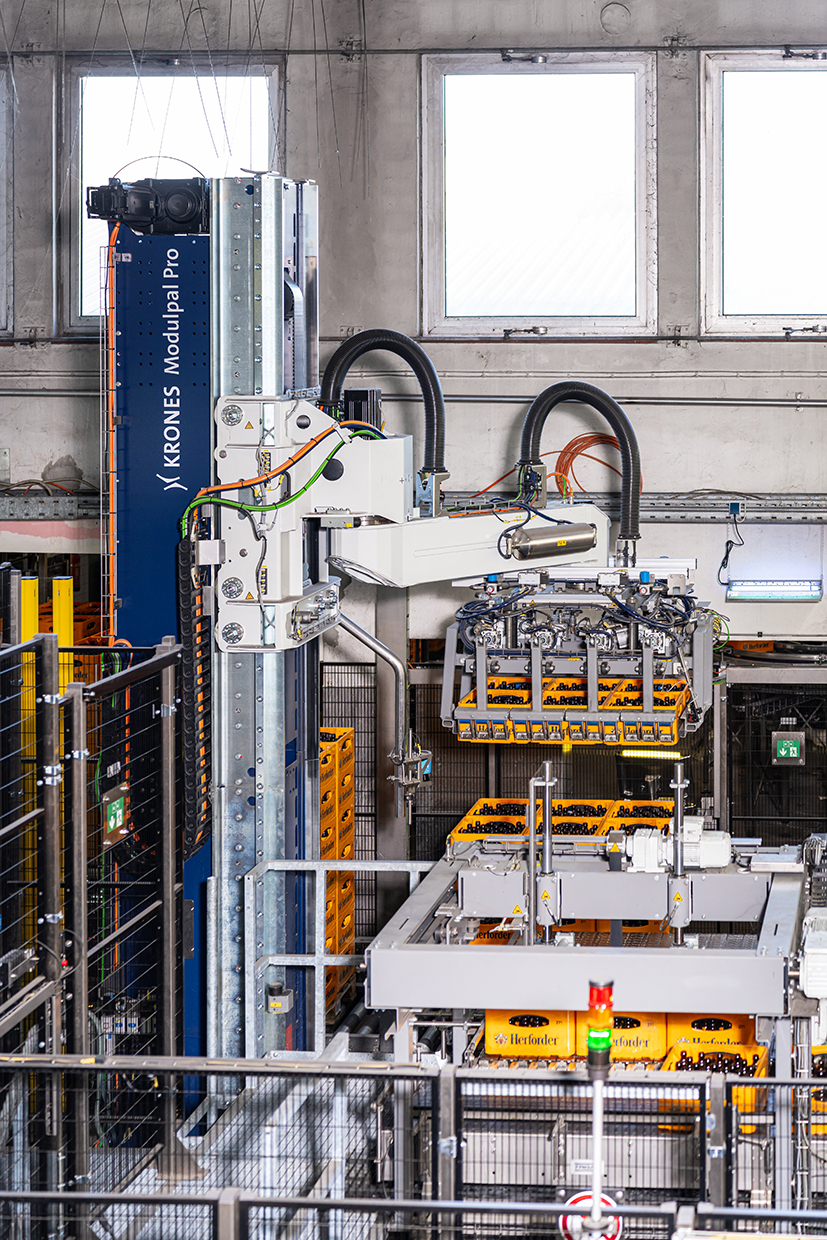

“Mind you, this flexibility goes hand in hand with complexity, or to put it another way with quite a few challenges,” says Henning Vormbrock. The solution? Automation and digitalisation. One example here is changing the handling parts at the packer and unpacker. What used to mean three hours of manual work for the operators is now performed by the machines themselves. All that’s left for the operators is a few clicks on the control panel. “In this way, both our employees’ workload and make-ready times are reduced enormously,” says Henning Vormbrock.

While there were hardly any digital features in the old bottling line, the new one now relies on smart control and real-time data. That has been a really big change for the team. But Henning Vormbrock is full of praise: “It’s great to see how they’ve all got on board.” The staff are supported by two digital solutions from Krones that make work easier for the planning team, in particular. One example of the digital upgrade is bottling schedule planning, which used to be quite complicated and was done as follows: Based on recent sales figures, one of the forepersons drew up the production plan and decided how many empties had to be fed into the line, and when. That required a lot of experience and that person’s permanent presence. Today this task is handled by the Line Management System, a software that records machine performance in real time: What are outputs running at? Is it necessary to supply the line with more empties? The type and number of empties needed in the line are shown on display boards, so the forklift truck drivers know what empties, and how many of each, they have to bring into the line. “Of course, that still requires some coordination, especially towards the end of an order, but the main calculation work is done by Line Management,” explains Henning Vormbrock.